TECHNICAL INFORMATION

Chemical properties of Stainless Steel

Chemical compositions of AISI (ASTM/ASME) and UNS austenitic stainless steel grades.

The data given is not intended to replace that shown in individual standards to which reference should always be made.

Standard 300 series austenitic grades:

| Designation | Chemical composition % by mass max unless stated | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| UNS No | SAE No | AISI No / Common Name | C | Si | Mn | P | S | Cr | Mo | Ni | Others |

| S30100 | 30301 | 301 | 0.15 | 1.00 | 2.00 | 0.045 | 0.030 | 16.0/18.0 | - | 6.00/8.00 | N 0.10 |

| S30103 | - | 301L | 0.03 | 1.00 | 2.00 | 0.045 | 0.030 | 16.0/18.0 | - | 6.00/8.00 | N 0.20 |

| S30153 | - | 301LN | 0.03 | 1.00 | 2.00 | 0.045 | 0.030 | 16.0/18.0 | - | 6.00/8.00 | N 0.07/0.20 |

| S30200 | 30302 | 302 | 0.15 | 0.75 | 2.00 | 0.045 | 0.030 | 17.0/19.0 | - | 8.00/10.0 | - |

| S30215 | 30302B | 302B | 0.15 | 2.00/3.00 | 2.00 | 0.045 | 0.030 | 17.0/19.0 | - | 8.00/10.0 | - |

| S30300 | 30303 | 303 | 0.15 | 1.00 | 2.00 | 0.20 | 0.15 min | 17.0/19.0 | 0.60 | 8.00/10.0 | Zr 0.60 |

| S30310 | - | XM-5 (303Plus x) | 0.15 | 1.00 | 2.50/4.50 | 0.20 | 0.25 min | 17.00/19.00 | - | 7.00/9.00 | - |

| S30323 | 30303Se | 303Se | 0.15 | 1.00 | 2.00 | 0.20 | 0.060 | 17.0/19.0 | - | 8.00/10.0 | Se 0.15 min |

| S30330 | - | 303Cu | 0.15 | 1.00 | 2.00 | 0.15 | 0.10 min | 17.00/19.00 | - | 6.00/10.00 | Cu 2.5/4.00; Se 0.10 |

| S30400 | 30304 | 304 | 0.08 | 0.75 | 2.00 | 0.045 | 0.030 | 18.0/20.0 | - | 8.00/10.5 | - |

| S30403 | 30304L | 304L | 0.03 | 0.75 | 2.00 | 0.045 | 0.030 | 18.0/20.0 | - | 8.00/12.0 | - |

| S30430 | - | 302HQ | 0.03 | 1.00 | 2.00 | 0.045 | 0.030 | 17.0/19.0 | - | 8.0/10.0 | Cu 3.0/4.0 |

| S30452 | - | XM-21 (304HN) | 0.08 | 1.00 | 2.00 | 0.045 | 0.030 | 18.0/20.0 | - | 8.00/10.00 | N 0.16/0.30 |

| S30453 | - | 304LN | 0.030 | 0.75 | 2.00 | 0.045 | 0.030 | 18.0/20.0 | - | 8.00/12.0 | N 0.10/0.16 |

| S30454 | - | - | 0.03 | 1.00 | 2.00 | 0.045 | 0.030 | 18.0/20.0 | - | 8.0/11.0 | N 0.16/0.30 |

| S30500 | 30305 | 305 | 0.12 | 1.00 | 2.00 | 0.045 | 0.030 | 17.0/19.0 | - | 10.5/13.0 | - |

| S30800 | 30308 | 308 | 0.08 | 1.00 | 2.00 | 0.045 | 0.030 | 19.0/21.0 | - | 10.0/12.0 | - |

| S31600 | 30316 | 316 | 0.08 | 1.00 | 2.00 | 0.045 | 0.030 | 16.0/18.0 | 2.00/3.00 | 10.0/14.0 | - |

| S31603 | 30316L | 316L | 0.03 | 1.00 | 2.00 | 0.045 | 0.030 | 16.0/18.0 | 2.00/3.00 | 10.0/14.0 | - |

| S31635 | - | 316Ti | 0.08 | 0.75 | 2.00 | 0.045 | 0.030 | 16.0/18.0 | 2.00/3.00 | 10.0/14.0 | Ti 5x (C+N) / 0.70 |

| S31640 | - | 316Cb | 0.08 | 0.75 | 2.00 | 0.045 | 0.030 | 16.0/18.0 | 2.00/3.00 | 10.0/14.0 | Nb 10x C / 1.10 |

| S31653 | - | 316LN | 0.03 | 0.75 | 2.00 | 0.045 | 0.030 | 16.0/18.0 | 2.00/3.00 | 10.0/14.0 | N 0.10/0.16 |

| S31700 | 30317 | 317 | 0.08 | 1.00 | 2.00 | 0.045 | 0.030 | 18.0/20.0 | 3.00/4.00 | 11.0/15.0 | - |

| S31703 | - | 317L | 0.030 | 0.75 | 2.00 | 0.045 | 0.030 | 18.0/20.0 | 3.00/4.00 | 11.0/15.0 | N 0.10 |

| S31725 | - | 317LM | 0.030 | 0.75 | 2.00 | 0.045 | 0.030 | 18.0/20.0 | 4.0/5.0 | 13.5/17.5 | N 0.20 |

| S31726 | - | 317LMN | 0.030 | 0.75 | 2.00 | 0.045 | 0.030 | 17.0/20.0 | 4.0/5.0 | 13.5/17.5 | N 0.10/0.20 |

| S31753 | - | 317LN | 0.030 | 0.75 | 2.00 | 0.045 | 0.030 | 18.0/20.0 | 3.0/4.0 | 11.0/15.0 | N 0.10/0.20 |

| S32100 | 30321 | 321 | 0.08 | 1.00 | 2.00 | 0.045 | 0.030 | 17.0/19.0 | - | 9.00/12.0 5 | Ti 5 x C min |

| S34700 | 30347 | 347 | 0.08 | 1.00 | 2.00 | 0.045 | 0.030 | 17.0/19.0 | - | 9.00/13.0 | Nb+Ta 10 x C min |

| S34720 | - | 347F | 0.08 | 1.00 | 2.00 | 0.040 | 0.18/0.35 | 17.00/19.00 | 0.75 | 9.00/12.00 | Nb 10xC / 1.10; Cu 0.75; Ta 0.05 |

| S34723 | - | 347FSe | 0.08 | 1.00 | 2.00 | 0.11/0.17 | 0.030 | 17.00/19.00 | 0.75 | 9.00/12.00 | Nb 10xC / 1.10; Cu 0.75; Se 0.15/0.35; Ta 0.05 |

| S34800 | 30348 | 348 | 0.08 | 0.75 | 2.00 | 0.045 | 0.030 | 17.0/19.0 | - | 9.00/13.0 | Nb+Ta 10 x C / 1.00; Ta:0.10 max; Co 0.20 |

| S38400 | 30384 | 384 | 0.08 | 1.00 | 2.00 | 0.045 | 0.030 | 15.0/17.0 | - | 17.0/19.0 | - |

Standard 200 series austenitic grades:

| Designation | Chemical composition % by mass max unless stated | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| UNS No | SAE No | AISI No / Common Name | C | Si | Mn | P | S | Cr | Mo | Ni | Others |

| S20100 | 30201 | 201 | 0.15 | 1.00 | 5.50/7.50 | 0.060 | 0.030 | 16.0/18.0 | - | 3.50/5.50 | N 0.25 |

| S20103 | - | - | 0.03 | 0.75 | 5.5/7.5 | 0.045 | 0.030 | 16.0/18.0 | - | 3.5/5.5 | N 0.25 |

| S20153 | - | - | 0.03 | 0.75 | 6.4/7.5 | 0.045 | 0.015 | 16.0/17.5 | - | 4.0/5.0 | N 0.10/0.25; Cu 1.00 |

| S20161 | - | Gall-Tough | 0.15 | 3.0/4.0 | 4.0/6.0 | 0.040 | 0.040 | 15.0/18.0 | - | 4.0/6.0 | N 0.08/0.20 |

| S20162 | - | - | 0.15 | 2.5/4.5 | 4.0/8.0 | 0.040 | 0.040 | 16.5/21.0 | 0.05/0.25 | 6.0/10.0 | N 0.05/0.25 |

| S20200 | 30202 | 202 | 0.15 | 1.00 | 7.50/10.0 | 0.060 | 0.030 | 17.0/19.0 | - | 4.00/6.00 | N 0.25 |

| S20300 | - | XM-1 (203EZ) | 0.08 | 1.00 | 5.0/6.5 | 0.045 | 0.18/0.35 | 16.0/18.0 | - | 5.0/6.5 | Cu 1.75/2.25 |

| S20400 | - | - | 0.030 | 1.00 | 7.0/9.0 | 0.040 | 0.030 | 15.0/17.0 | - | 1.50/3.00 | N 0.15/0.30 |

| S20500 | - | 205 | 0.12/0.25 | 1.00 | 14.0/15.5 | 0.060 | 0.030 | 16.5/18.0 | - | 1.0/1.7 | N 0.32/0.40 |

| S20910 | - | XM-19 (Nitronic 50) | 0.06 | 0.75 | 4.0/6.0 | 0.040 | 0.030 | 20.5/23.5 | 1.50/3.00 | 11.5/13.5 | Nb 0.10/0.30; V 0.10/0.30 |

| S21400 | - | XM-31 (Tenelon) | 0.12 | 0.30/1.00 | 14.0/16.0 | 0.045 | 0.030 | 17.0/18.5 | - | 1.00 | - |

| S21460 | - | XM-14 | 0.12 | 0.75 | 14.0/16.0 | 0.060 | 0.030 | 17.0/19.0 | - | 5.0/6.0 | N 0.35/0.50 |

| S21600 | - | XM-17 (216) | 0.08 | 0.75 | 7.5/9.0 | 0.045 | 0.030 | 17.5/22.0 | 2.00/3.00 | 5.0/7.0 | N 0.25/0.50 |

| S21603 | - | XM-18 (216L) | 0.03 | 0.75 | 7.5/9.0 | 0.045 | 0.030 | 17.5/22.0 | 2.00/3.00 | 5.0/7.0 | N 0.25/0.50 |

| S21800 | - | Nitronic 60 | 0.10 | 3.5/4.5 | 7.0/9.0 | 0.060 | 0.030 | 16.0/18.0 | - | 8.0/9.0 | N 0.08/0.18 |

| S21900 | - | 21-6-9 (Nitronic 40) | 0.08 | 1.00 | 8.00/10.00 | 0.045 | 0.030 | 19.0/21.50 | - | 5.50/7.50 | N 0.15/0.40 |

| S21904 | - | XM-11 (Nitronic 40) | 0.04 | 1.00 | 8.00/10.00 | 0.045 | 0.030 | 19.00/21.50 | - | 5.50/7.50 | N 0.15/0.40 |

| S24000 | - | XM-29 (Nitronic 33) | 0.08 | 0.75 | 11.5/14.5 | 0.060 | 0.030 | 17.0/19.0 | - | 2.3/3.7 | N 0.20/0.40 |

| S24100 | - | 18-2Mn (Nitronic 32) | 0.15 | 1.00 | 11.0/14.0 | 0.045 | 0.030 | 16.5/19.00 | - | 0.50/2.50 | N 0.20/0.45 |

| S28200 | - | 18-18 Plus | 0.15 | 1.00 | 17.00/19.00 | 0.045 | 0.030 | 17.00/19.00 | 0.75/1.25 | - | N 0.40/0.60; Cu 0.75/1.25 |

Special austenitic grades:

| Designation | Chemical composition % by mass max unless stated | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| UNS No | SAE No | AISI No / Common Name | C | Si | Mn | P | S | Cr | Mo | Ni | Others | N08020 | - | 20Cb-3 | 0.07 | 1.00 | 2.00 | 0.045 | 0.035 | 19.0/21.0 | 2.00/3.00 | 32.0/38.0 | Cu 3.0/4.0; Nb 8xC / 1.00 |

| N08024 | - | 20Mo-4 | 0.03 | 0.50 | 1.00 | 0.035 | 0.035 | 22.50/25.00 | 3.50/5.00 | 35.00/40.00 | Cu 0.50/1.50; Nb+Ta 0.15/0.35 |

| N08026 | - | 20Mo6 | 0.03 | 0.50 | 1.00 | 0.03 | 0.03 | 22.00/26.00 | 5.00/6.70 | 33.0/37.20 | Cu 2.00/4.00; N 0.10/0.16 |

| N08028 | - | Sanicro28 | 0.030 | 1.0 | 2.50 | 0.030 | 0.030 | 26.0/28.0 | 3.0/4.0 | 30.0/34.0 | Cu 0.6/1.4 |

| N08366 | - | AL-6X | 0.035 | 1.00 | 2.00 | 0.040 | 0.030 | 20.00/22.00 | 6.00/7.00 | 23.50/25.50 | - |

| N08367 | - | AL-6XN | 0.030 | 1.00 | 2.00 | 0.040 | 0.030 | 20.0/22.0 | 6.0/7.0 | 23.5/25.5 | Cu 0.75; N 0.18/0.25 |

| N08700 | - | JS700 | 0.04 | 1.00 | 2.00 | 0.040 | 0.030 | 19.0/23.0 | 4.3/5.0 | 24.0/26.0 | Cu 0.50; Nb 8xC / 0.40 |

| N08904 | - | 904L | 0.020 | 1.00 | 2.00 | 0.045 | 0.035 | 19.0/23.0 | 4.0/5.0 | 23.0/28.0 | Cu 1.0/2.0 |

| N08925 | - | 1925hMo | 0.020 | 0.50 | 1.0 | 0.045 | 0.030 | 19.0/21.0 | 6.0/7.0 | 24.0/26.0 | Cu 0.8/1.5; N 0.1/0.2 |

| N08926 | - | - | 0.020 | 1.50 | 2.00 | 0.030 | 0.010 | 19.0/21.0 | 6.0/7.0 | 24.0/26.0 | Cu 0.5/1.5; N 0.15/0.25 |

| S30600 | - | Cronifer 1815 LCSi | 0.018 | 3.7/4.3 | 2.00 | 0.020 | 0.020 | 17.0/18.5 | 0.20 | 14.0/15.5 | Cu 0.50 |

| S30601 | - | - | 0.015 | 5.0/5.6 | 0.50/0.80 | 0.030 | 0.013 | 17.0/18.0 | 0.20 | 17.0/18.0 | Cu 0.05; N 0.35 |

| S31050 | - | 310MoLN | 0.020 | 0.50 | 2.00 | 0.030 | 0.010 | 24.0/26.0 | 1.60/2.60 | 0.09/0.15 | N 0.09/0.15 |

| S31254 | - | 254SMO | 0.020 | 0.80 | 1.00 | 0.030 | 0.010 | 19.5/20.5 | 6.0/6.5 | 17.5/18.5 | Cu 0.50/1.00; N 0.18/0.22 |

| S31266 | - | - | 0.030 | 1.00 | 2.0/4.0 | 0.035 | 0.020 | 23.0/25.0 | 5.2/6.2 | 21.0/24.0 | Cu 1.00/2.50; N 0.35/0.60; W 1.50/2.50 |

| S31277 | - | - | 0.020 | 0.50 | 3.00 | 0.030 | 0.010 | 20.5/23.0 | 6.5/8.0 | 26.0/28.0 | Cu 0.5/1.50; N 0.30/0.40 |

| S32050 | - | - | 0.030 | 1.00 | 1.50 | 0.035 | 0.020 | 22.0/24.0 | 6.0/6.8 | 20.0/23.0 | Cu 0.40 |

| S32615 | - | - | 0.07 | 4.8/6.0 | 2.00 | 0.045 | 0.030 | 16.5/19.5 | 0.30/1.50 | 19.0/22.0 | Cu 1.50/2.50 |

| S32654 | - | 654SMO | 0.020 | 0.50 | 2.0/4.0 | 0.030 | 0.005 | 24.0/25.0 | 7.0/8.0 | 21.0/23.0 | Cu 0.30/0.60; N 0.45/0.55 |

| S34565 | - | Nirosta 4565S | 0.030 | 1.00 | 5.0/7.0 | 0.030 | 0.010 | 23.0/25.0 | 4.0/5.0 | 16.0/18.0 | N 0.40/0.60; Nb 10x C / 1.00 |

| S35135 | - | - | 0.08 | 0.60/1.00 | 1.00 | 0.045 | 0.015 | 20.0/25.0 | 4.0/4.8 | 30./38.0 | Ti 0.40/1.00 |

| S38100 | - | XM-15 (18-18-2) | 0.08 | 1.50/2.50 | 2.00 | 0.030 | 0.030 | 17.0/19.0 | - | 17.5/18.5 | - |

| S38815 | - | - | 0.030 | 5.5/6.5 | 2.00 | 0.040 | 0.020 | 13.0/15.0 | 0.75/1.50 | 13.0/17.0 | Cu 0.75/1.50; Al 0.30 |

Chemical compositions of AISI (ASTM/ASME) and UNS ferritic stainless steel grades:

| Designation | Chemical composition % by mass max unless stated | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| UNS No | SAE No | AISI No / Common Name | C | Si | Mn | P | S | Cr | Mo | Ni | Others |

| S18200 | - | XM-34 (18-2FM) | 0.08 | 1.00 | 2.50 | 0.04 | 0.15 min | 17.5/19.5 | 1.50/2.50 | - | - |

| S18235 | - | - | 0.025 | 1.00 | 0.50 | 0.030 | 0.15/0.35 | 17.5/18.5 | 2.00/2.50 | 1.00 | N 0.025; (C+N) 0.035; Ti 0.30/1.00 |

| S40300 | 51403 | 403 | 0.15 | 0.50 | 1.00 | 0.040 | 0.030 | 11.5/13.0 | - | - | - |

| S40500 | 51405 | 405 | 0.08 | 1.00 | 1.00 | 0.040 | 0.030 | 11.5/14.5 | - | - | Al 0.10./0.30 |

| S40800 | - | - | 0.08 | 1.00 | 1.00 | 0.045 | 0.045 | 11.5/13.0 | - | 0.50 | Ti 12xC/1.10 |

| S40900 | 51409 | 409 | 0.08 | 1.00 | 1.00 | 0.045 | 0.045 | 10.5/11.75 | - | 0.50 | Ti 6xC/0.75 |

| S40910 | - | - | 0.030 | 1.00 | 1.00 | 0.040 | 0.020 | 10.5/11.7 | - | 0.50 | N 0.030; Ti: 6x(C+N)/0.50; Nb 0.17 |

| S40920 | - | - | 0.030 | 1.00 | 1.00 | 0.040 | 0.020 | 10.5/11.7 | - | 0.50 | N 0.030; Ti 0.15/0.50; Nb 0.10 |

| S40930 | - | - | 0.030 | 1.00 | 1.00 | 0.040 | 0.020 | 10.5/11.7 | - | 0.50 | N 0.030; (Ti+Nb) [0.08+8x(C+N)]/0.75; Ti 0.05 |

| S40945 | - | - | 0.030 | 1.00 | 1.00 | 0.040 | 0.030 | 10.5/11.7 | - | 0.50 | N 0.030; Ti 0.05/0.20; Nb 0.18/0.40 |

| S40975 | - | - | 0.030 | 1.00 | 1.00 | 0.040 | 0.030 | 10.5/11.7 | - | 0.50/1.00 | N 0.030; Ti: 6x(C+N)/0.75 |

| S40976 | - | - | 0.030 | 1.00 | 1.00 | 0.040 | 0.030 | 10.5/11.7 | - | 0.75/1.00 | N 0.040; Nb 10x(C+N)-0.80 |

| S40977 | - | - | 0.030 | 1.00 | 1.00 | 0.040 | 0.015 | 10.5/12.5 | - | 0.30/1.00 | N 0.030 |

| S41003 | - | - | 0.030 | 1.00 | 1.50 | 0.040 | 0.030 | 10.5/12.5 | - | 1.50 | - |

| S41008 | - | 410S | 0.08 | 1.00 | 1.00 | 0.040 | 0.030 | 11.5/13.5 | - | - | - |

| S41045 | - | - | 0.030 | 1.00 | 1.00 | 0.040 | 0.030 | 12.0/13.0 | - | 0.50 | N 0.030; Nb 9x(C+N)/0.60 |

| S41050 | - | - | 0.04 | 1.00 | 1.00 | 0.040 | 0.030 | 10.5/12.5 | - | 0.60/1.10 | N 0.10 |

| S41500 | - | - | 0.05 | 0.60 | 0.50/1.00 | 0.030 | 0.030 | 11.5/14.0 | 0.50/1.00 | 3.5/5.5 | - |

| S41603 | - | - | 0.08 | 1.00 | 1.25 | 006 | 0.15min | 12.0/14.0 | - | - | - |

| S42035 | - | - | 0.08 | 1.00 | 1.00 | 0.045 | 0.030 | 13.5/15.5 | 0.2/1.2 | - | Ti 0.30/0.50 |

| S43000 | 51430 | 430 | 0.12 | 1.00 | 1.00 | 0.040 | 0.030 | 16.0/18.0 | - | - | - |

| S43020 | 51430F | 430F | 0.12 | 1.00 | 1.25 | 0.060 | 0.15 min | 16.0/18.0 | 0.60 | - | - |

| S43023 | 51430FSe | 430FSe | 0.12 | 1.00 | 1.25 | 0.060 | 0.060 | 16.0/18.0 | - | - | Se 0.15 |

| S43036 | - | 430Ti | 0.10 | 1.00 | 1.00 | 0.040 | 0.030 | 16.00/19.50 | - | 0.75 | Ti 5xC/0.75 |

| S43400 | 51434 | 434 | 0.08 | 1.00 | 1.00 | 0.040 | 0.030 | 16.0/18.0 | 0.75/1.25 | - | - |

| S43600 | 51436 | 436 | 0.08 | 1.00 | 1.00 | 0.040 | 0.030 | 16.0/18.0 | 0.75/1.25 | - | Nb+Ta 5xC/0.70 |

| S44200 | 51442 | 442 | 0.20 | 1.00 | 1.00 | 0.040 | 0.035 | 18.0/23.0 | - | - | - |

Special ferritic grades:

| Designation | Chemical composition % by mass max unless stated | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| UNS No | SAE No | AISI No / Common Name | C | Si | Mn | P | S | Cr | Mo | Ni | Others |

| S32803 | - | Cronifer 2803Mo | 0.015 | 0.55 | 0.50 | 0.020 | 0.0035 | 28.0/29.0 | 1.80/2.50 | 3.0/4.0 | N 0.020; (C+N) 0.030; Nb 0.15/0.50 |

| S43035 | - | 435 | 0.030 | 1.00 | 1.00 | 0.040 | 0.030 | 17.0/19.0 | - | 0.50 | Ti [0.20+4(C+N)] / 1.10; Al 0.15 |

| S43900 | 51439 | 439 | 0.07 | 1.00 | 1.00 | 0.040 | 0.030 | 17.0/19.0 | - | 0.50 | Ti [0.20+4(C+N)] / 1.10; Al 0.15; N:0.04 |

| S43903 | 51439LL | 439LL | 0.014 | 1.00 | 1.00 | 0.040 | 0.030 | 17.0/19.0 | - | 0.50 | Ti [0.20+4(C+N)] / 1.10; Al 0.15; N:0.04 |

| S43932 | - | - | 0.030 | 1.00 | 1.00 | 0.040 | 0.030 | 17.0/19.0 | - | 0.50 | N 0.030; (Ti+Nb) [0.20+4(C+N)] / 0.75; Al 0.15 |

| S43940 | - | - | 0.030 | 1.00 | 1.00 | 0.040 | 0.015 | 17.5/18.5 | - | 0.50 | Ti 0.10/0.60; Nb [0.30+(3xC)] min |

| S44400 | - | 444 18Cr-2Mo | 0.025 | 1.00 | 1.00 | 0.040 | 0.030 | 17.5/19.5 | 1.75/2.50 | 1.00 | N 0.035; (Ti+Nb)[0.20+4(C+N)] / 0.80 |

| S44500 | - | - | 0.020 | 1.00 | 1.00 | 0.040 | 0.012 | 19.0/21.0 | - | 0.60 | N 0.03; Cu 0.30/0.60; Nb 10x(C+N) / 0.80 |

| S44626 | - | XM-33 (26-1Ti) | 0.06 | 0.75 | 0.75 | 0.040 | 0.020 | 25.0/27.0 | 0.75/1.50 | 0.50 | N 0.04; Cu 0.20; Ti 0.20/1.00 |

| S44627 | - | XM-27 | 0.010 | 0.40 | 0.40 | 0.020 | 0.020 | 25.0/27.0 | 0.75/1.50 | 0.50 | N 0.015; Cu 0.20; Nb 0.05/0.20; (Ni+Cu) 0.50 |

| S44635 | - | Nu Monit (25-4-4) | 0.025 | 0.75 | 1.00 | 0.040 | 0.030 | 24.5/26.0 | 3.5/4.5 | 3.5/4.5 | N 0.035; (Ti+Nb){0.20+4(C+N)] / 0.80 |

| S44660 | - | Sea-cure (26-3-3) | 0.030 | 1.00 | 1.00 | 0.040 | 0.030 | 25.0/28.0 | 3.0/4.0 | 1.0/3.5 | N 0.040; (Ti+Nb)0.20 / 1.00; (Ti+Nb) [6x(C+N)] min |

| S44700 | - | 29-4 | 0.010 | 0.20 | 0.30 | 0.025 | 0.020 | 28.0/30.0 | 3.5/4.2 | 0.15 | N 0.020; Cu 0.15; (C+N) 0.025 |

| S44735 | - | - | 0.030 | 1.00 | 1.00 | 0.040 | 0.030 | 28.0/30.0 | 3.6/4.2 | 1.00 | N 0.045; (Ti+Nb)0.20/1.00; (Ti+Nb) 6x (C+N) min |

| S44800 | - | 29-4-2 | 0.010 | 0.20 | 0.30 | 0.025 | 0.020 | 28.0/30.0 | 3.5/4.2 | 2.00/2.50 | N 0.020; Cu 0.15; (C+N) 0.025 |

| S46800 | - | - | 0.030 | 1.00 | 1.00 | 0.040 | 0.030 | 18.0/20.0 | - | 0.50 | N 0.030; Ti 0.07/0.30; Nb 0.10/0.60; (Ti+Nb) [0.20+4(C+N)] / 0.80 |

Chemical compositions of AISI (ASTM/ASME) and UNS heat resisting stainless steel grades:

| Designation | Chemical composition % by mass max unless stated | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| UNS No | SAE No | AISI No / Common Name | C | Si | Mn | P | S | Cr | Mo | Ni | Others |

| S21500 | - | Esshete 1250 | 0.06/0.15 | 0.20/1.0 | 5.50/7.0 | 0.045 | 0.030 | 14.0/16.0 | 0.80/1.20 | 9.00/11.0 | B 0.003/0.009; Nb 0.75/1.25; V 0.15/0.40 |

| S30409 | - | 304H | 0.04/0.10 | 0.75 | 2.00 | 0.045 | 0.030 | 18.0/20.0 | - | 8.0/10.5 | - |

| S30415 | - | 153MA | 0.04/0.06 | 1.00/2.00 | 0.80 | 0.045 | 0.030 | 18.0/19.0 | - | 9.0/10.0 | N 0.12/0.18; Ce 0.03/0.08 |

| S30451 | - | 304N | 0.08 | 0.75 | 2.00 | 0.045 | 0.030 | 18.0/20.0 | - | 8.0/10.5 | N 0.10/0.16 |

| S30452 | - | 304HN (XM-21) | 0.08 | 0.75 | 2.00 | 0.045 | 0.030 | 18.0/20.0 | - | 8.0/10.5 | N 0.16/0.30 |

| S30615 | - | RA85H | 0.16/0.24 | 3.2/4.0 | 2.00 | 0.030 | 0.030 | 17.0/19.5 | - | 13.5/16.0 | Al 0.80/1.50 |

| S30815 | - | 253MA | 0.05/0.10 | 1.40/2.00 | 0.80 | 0.040 | 0.030 | 20.0/22.0 | - | 10.0/12.0 | N 0.14/0.20; Ce 0.03/0.08 |

| S30900 | 30309 | 309 | 0.20 | 1.00 | 2.00 | 0.045 | 0.030 | 22.0/24.0 | - | 12.0/15.0 | - |

| S30908 | 30309S | 309S | 0.08 | 0.75 | 2.00 | 0.045 | 0.030 | 22.0/24.0 | - | 12.0/15.0 | - |

| S30909 | - | 309H | 0.04/0.10 | 0.75 | 2.00 | 0.045 | 0.030 | 22.0/24.0 | - | 12.0/15.0 | - |

| S30940 | - | 309Cb | 0.08 | 0.75 | 2.00 | 0.045 | 0.030 | 22.0/24.0 | - | 12.0/16.0 | Nb 10xC / 1.10 |

| S30941 | - | 309HCb | 0.04/0.10 | 0.75 | 2.00 | 0.045 | 0.030 | 22.0/24.0 | - | 12.0/16.0 | Nb 10xC / 1.10 |

| S31000 | 30310 | 310 | 0.25 | 1.50 | 2.00 | 0.045 | 0.030 | 24.0/26.0 | - | 19.0/22.0 | - |

| S31008 | 30310S | 310S | 0.08 | 1.50 | 2.00 | 0.045 | 0.030 | 24.0/26.0 | - | 19.0/22.0 | - |

| S31009 | - | 310H | 0.04/0.10 | 0.75 | 2.00 | 0.045 | 0.030 | 24.0/26.0 | - | 19.0/22.0 | - |

| S31040 | - | 310Cb | 0.08 | 1.50 | 2.00 | 0.045 | 0.030 | 24.0/26.0 | - | 19.0/22.0 | Nb 10xC / 1.10 |

| S31041 | - | 310HCb | 0.04/0.10 | 0.75 | 2.00 | 0.045 | 0.030 | 24.0/26.0 | - | 19.0/22.0 | Nb 10xC / 1.10 |

| S31400 | 30314 | 314 | 0.25 | 1.50/3.00 | 2.00 | 0.045 | 0.030 | 23.0/26.0 | - | 19.0/22.0 | - |

| S31609 | - | 316H | 0.04/0.10 | 0.75 | 2.00 | 0.045 | 0.030 | 16.0/18.0 | 2.00/3.00 | 10.0/14.0 | - |

| S31651 | - | 316N | 0.08 | 0.75 | 2.00 | 0.045 | 0.030 | 16.0/18.0 | 2.00/3.00 | 10.0/14.0 | N 0.10/0.16 |

| S32109 | - | 321H | 0.04/0.10 | 0.75 | 2.00 | 0.045 | 0.030 | 17.0/19.0 | - | 9.0/12.0 | Ti 4x(C+N) / 0.70 |

| S33228 | - | - | 0.04/0.08 | 0.30 | 1.00 | 0.020 | 0.015 | 26.0/28.0 | - | 31.0/33.0 | Al 0.025;Ce 0.05/0.10; Nb 0.6/1.0 |

| S33400 | - | 334 | 0.08 | 1.00 | 1.00 | 0.030 | 0.015 | 18.0/22.0 | - | 19.0/21.0 | Al 0.15/0.60; Ti 0.15/0.60 |

| S34709 | - | 347H | 0.04/0.10 | 0.75 | 2.00 | 0.045 | 0.030 | 17.0/19.0 | - | 9.0/13.0 | Nb 8xC /1.00 |

| S34800 | - | 348 | 0.08 | 0.75 | 2.00 | 0.045 | 0.030 | 17.0/19.0 | - | 9.0/13.0 | Nb+Ta 10xC / 1.00; Ta 0.10; Co 0.20 |

| S34809 | - | 348H | 0.04/0.10 | 0.75 | 2.00 | 0.045 | 0.030 | 17.0/19.0 | - | 9.0/13.0 | Nb+Ta 10xC /1.00; Ta 0.10; Co 0.20 |

| S35045 | - | - | 0.06/0.10 | 1.00 | 1.50 | 0.045 | 0.015 | 25.0/29.0 | - | 32.0/37.0 | Al 0.15/0.60; Ti 0.15/0.60 |

| S35315 | - | 353MA | 0.04/0.08 | 1.20/2.00 | 2.00 | 0.040 | 0.030 | 24.0/26.0 | - | 34.0/36.0 | N 0.12/0.18; Ce 0.03/0.10 |

| S41041 | - | - | 0.13/0.18 | 0.50 | 0.40/0.60 | 0.030 | 0.030 | 11.50/13.00 | 0.20 | 0.50 | Al 0.05; Nb 0.15 |

| S41425 | - | - | 0.05 | 0.50 | 0.50/1.00 | 0.020 | 0.005 | 12.0/15.0 | 1.50/2.00 | 4.0/7.0 | N 0.06/0.12; Cu 0.30 |

| S41800 | - | Greek Ascoloy (615) | 0.15/0.20 | 0.50 | 0.50 | 0.040 | 0.030 | 12.00/14.00 | 0.50 | 1.80/2.20 | W 2.50/3.50 |

| S42200 | - | 616 | 0.20/0.25 | 0.50 | 0.50/1.00 | 0.025 | 0.025 | 11.00/12.50 | 0.90/1.25 | 0.50/1.00 | V 0.20/0.30; W 0.90/1.25 |

| S42300 | - | Lapelloy (619) | 0.27/0.32 | 0.50 | 0.95/1.35 | 0.025 | 0.025 | 11.00/12.00 | 2.50/3.00 | 0.50 | V 0.20/0.30 |

| S44300 | - | MT443 | 0.20 | 1.00 | 1.00 | 0.040 | 0.030 | 18.0/23.0 | - | 0.50 | Cu 0.90/1.25 |

| S44600 | 51446 | 446 | 0.20 | 1.00 | 1.50 | 0.040 | 0.030 | 23.0/27.0 | - | - | N 0.25 |

| S64152 | - | XM-32 | 0.08/0.15 | 0.35 | 0.50/0.90 | 0.025 | 0.025 | 11.00/12.50 | 1.50/2.00 | 2.00/3.00 | N 0.01/0.05; V 0.25/0.40 |

| N08800 | - | 800 (332) | 0.10 | 1.00 | 1.50 | 0.045 | 0.015 | 19.0/23.0 | - | 30.0/35.0 | Fe 39.5 min; Al 0.15/0.60; Ti 0.15/0.60 |

| N08810 | - | 800H | 0.05/0.10 | 1.00 | 1.50 | 0.045 | 0.015 | 19.0/23.0 | 30.0/35.0 | 30.0/35.0 | Cu 0.75; Fe 39.5 min; Al 0.15/0.60; Ti 0.15/0.60 |

| N08811 | - | - | 0.06/0.10 | 1.00 | 1.50 | 0.040 | 0.015 | 19.0/23.0 | - | 30.0/35.0 | Cu 0.75; Fe 39.5 min; Al 0.15/0.60; Ti 0.15/0.60 |

Chemical compositions of AISI (ASTM/ASME) and UNS martensitic and precipitation hardening stainless steel grades:

| Designation | Chemical composition % by mass max unless stated | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| UNS No | SAE No | AISI No / Common Name | C | Si | Mn | P | S | Cr | Mo | Ni | Others |

| S13800 | - | XM-13 PH13-8Mo | 0.05 | 0.10 | 0.20 | 0.010 | 0.008 | 12.25/13.25 | 2.00/2.50 | 7.50/8.50 | N 0.01; Al 0.90/1.35 |

| S15500 | - | XM-12 15-5PH | 0.07 | 1.00 | 1.00 | 0.040 | 0.030 | 14.0/15.5 | - | 3.50/5.50 | Cu 2.5/4.5; Nb 0.15/0.45 |

| S15700 | - | 632 15-7PH | 0.09 | 1.00 | 1.00 | 0.040 | 0.030 | 14.00/16.00 | 2.00/3.00 | 6.50/7.25 | Al 0.75/1.50 |

| S17400 | - | 630 17-4PH | 0.07 | 1.00 | 1.00 | 0.040 | 0.030 | 15.5/17.5 | - | 3.00/5.00 | Cu 3.00/5.00; Al 0.15/0.45 |

| S17600 | - | 635 | 0.08 | 1.00 | 1.00 | 0.040 | 0.030 | 16.00/17.50 | - | 6.00/7.50 | Al 0.40; Ti 0.40/1.20 |

| S17700 | - | 631 17-7PH | 0.09 | 1.00 | 1.00 | 0.040 | 0.040 | 16.00/18.00 | - | 6.50/7.75 | Al 0.75/1.50 |

| S35000 | - | 633 | 0.07/0.11 | 0.50 | 0.50/1.25 | 0.040 | 0.030 | 16.00/17.00 | 2.50/3.25 | 4.00/5.00 | N 0.07/0.13 |

| S35500 | - | 634 | 0.10/0.15 | 0.50 | 0.50/1.25 | 0.040 | 0.030 | 15.00/16.00 | 2.50/3.25 | 4.00/5.00 | N 0.07/0.13 |

| S41000 | 51410 | 410 | 0.15 | 1.00 | 1.00 | 0.040 | 0.030 | 11.5/13.5 | - | - | - |

| S41040 | - | XM-30 | 0.18 | 1.00 | 1.00 | 0.040 | 0.030 | 11.0/13.0 | - | - | Nb 0.05/0.30 |

| S41400 | 51414 | 414 | 0.15 | 1.00 | 1.00 | 0.040 | 0.030 | 11.5/13.5 | - | 1.25/2.50 | - |

| S41500 | - | - | 0.05 | 0.60 | 0.50/1.00 | 0.030 | 0.030 | 11.5/14.0 | 0.50/1.00 | 3.5/5.5 | - |

| S41600 | 51416 | 416 | 0.15 | 1.00 | 1.25 | 0.060 | 0.15 min | 12.0/14.0 | 0.60 | - | Zr 0.60 |

| S41610 | - | XM-6 (416 Plus X) | 0.15 | 1.00 | 1.50/2.50 | 0.06 | 0.15 min | 12.0/14.0 | - | - | - |

| S41623 | 51416Se | 416Se | 0.15 | 1.00 | 1.25 | 0.060 | 0.060 | 12.0/14.0 | - | - | Se 0.15 min |

| S42000 | 51420 | 420 | 0.15 min | 1.00 | 1.00 | 0.040 | 0.030 | 12.0/14.0 | - | - | - |

| S42010 | - | Trim Rite | 0.15/0.30 | 1.00 | 1.00 | 0.040 | 0.030 | 13.5/15.00 | 0.40/0.85 | 0.35/0.85 | - |

| S42020 | 51420F | 420F | 0.15 min | 1.00 | 1.25 | 0.060 | 0.15 min | 12.0/14.0 | 0.60 | - | - |

| S42023 | 51420FSe | 420FSe | 0.30/0.40 | 1.00 | 1.25 | 0.060 | 0.060 | 12.0/14.0 | - | - | Se 0.15 min |

| S42900 | 51429 | 429 | 0.12 | 1.00 | 1.00 | 0.040 | 0.030 | 14.0/16.0 | - | - | - |

| S43100 | 51431 | 431 | 0.20 | 1.00 | 1.00 | 0.040 | 0.030 | 15.0/17.0 | - | 1.25/2.50 | - |

| S44002 | 51440A | 440A | 0.60/0.75 | 1.00 | 1.00 | 0.040 | 0.030 | 16.0/18.0 | 0.75 | - | - |

| S44003 | 51440B | 440B | 0.75/0.95 | 1.00 | 1.00 | 0.040 | 0.030 | 16.0/18.0 | 0,75 | - | - |

| S44004 | 51440C | 440C | 0.95/1.20 | 1.00 | 1.00 | 0.040 | 0.030 | 16.0/18.0 | 0.75 | - | - |

| S44020 | 51440F | 440F | 0.95/1.20 | 1.00 | 1.25 | 0.060 | 0.15 min | 16.0/18.0 | 0.75 | - | Zr 0.75 |

| S44023 | 51440FSe | 440FSe | 0.95/1.20 | 1.00 | 1.25 | 0.060 | 0.060 | 16.0/18.0 | - | - | Se 0.15 min |

| S45000 | - | XM-25 Custom 450 | 0.05 | 1.00 | 1.00 | 0.030 | 0.030 | 14.00/16.00 | 0.50/1.00 | 5.00/7.00 | Cu 1.25/1.75; Nb 8xC min |

| S45500 | - | XM-16 Custom 455 | 0.05 | 0.50 | 0.50 | 0.040 | 0.030 | 11.00/12.50 | 0.50 | 7.50/9.50 | Cu 1.50/2.50; Nb 0.10/0.50 |

| S45503 | - | - | 0.010 | 0.20 | 0.50 | 0.010 | 0.010 | 11.00/12.50 | 0.50 | 7.50/9.50 | Cu 1.50/2.50; Ti 1.00/1.35 |

| S46500 | - | - | 0.02 | 0.25 | 0.25 | 0.015 | 0.010 | 11.00/12.50 | 0.75/1.25 | 10.75/11.25 | Mo 0.75/1.25; Ti 1.50/1.80 |

| S66286 | - | A286 | 0.08 | 1.00 | 2.00 | 0.040 | 0.030 | 13.50/16.00 | 1.00/1.50 | 24.0/27.0 | Al 0.35; B 0.0010/0.010; Ti 1.90/2.35; V 0.10/0.50 |

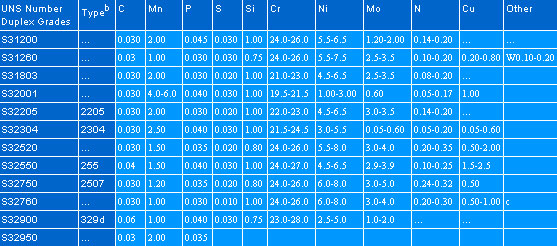

Composition of Duplex Stainless Steel:

Mechanical properties of Stainless Steel

| MECHANICAL PROPERTIES | |||||

|---|---|---|---|---|---|

| Grade | Tensile Strength Mpa, (Min) |

Yield Strength Mpa, (Min) |

%Age Elongation in 50mm gauge length min |

Hardness (Max) | |

| BHN | Rb | ||||

| 301 | 515 | 205 | 40 | 217 | 95 |

| 304 | 515 | 205 | 40 | 201 | 92 |

| 304L | 485 | 170 | 40 | 201 | 92 |

| 310S | 515 | 205 | 40 | 217 | 95 |

| 316 | 515 | 205 | 40 | 217 | 95 |

| 316L | 485 | 170 | 40 | 217 | 95 |

| 317 | 515 | 205 | 35 | 217 | 95 |

| 317L | 515 | 205 | 40 | 217 | 95 |

| 321 | 515 | 205 | 40 | 217 | 95 |

| 347 | 515 | 205 | 40 | 201 | 92 |

| 409 | 380 | 170 | 20 | 179 | 88 |

| 409M | 430 | 275 | 20 | 187 | 90 |

| 410S | 415 | 205 | 22 | 183 | 89 |

| 410 | 450 | 205 | 20 | 217 | 89 |

| 420 | 700( max ) | - | 15 | 217 | 95 |

| 430 | 450 | 205 | 22 | 183 | 89 |

| JSL AUS | 515 | 205 | 40 | 217 | 95 |

| JS- 203 | 515 | 205 | 40 | 217 | 95 |

| 301M | 515 | 205 | 40 | 217 | 95 |

Specification of Carbon Steel

CARBON STEEL, ALLOY STEEL, LOW TEMP, PIPE & TUBES SPECIFICATION

| CHEMICAL ANALYSIS | MECHANICAL PROPERTIES | SPECIFIC REQUIREMENT | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Tensile Strength | Yield Strength | Elongation | ||||||||||

| Specification | WT | C% | Mn% | P% MAX | S% MAX | Si% | Cr% | Mo% | Mpa | Mpa | 50mm MIN Longitudinal | |

| ASTM A 53/A ASTM A 53/B ASTM A 106/A ASTM A 106/B ASTM A 106/C |

AW AW AW AW AW |

0.25MAX 0.30MAX 0.25MAX 0.30MAX 0.35MAX |

0.95MAX 1.20MAX 0.27-0.93 0.29-1.06 0.29-1.06 |

0.050 0.050 0.025 0.025 0.025 |

0.060 0.060 0.025 0.025 0.025 |

- - 0.10MIN 0.10MIN 0.10MIN |

- - 0.40MAX 0.40MAX 0.40MAX |

- - 0.15MAX 0.15MAX 0.15MAX |

331MIN 413MIN 330MIN 415MIN 485MIN |

207 MIN 240MIN 205MIN 240MIN 275MIN |

36 29.5 35/28 30/22 30/22 |

Cr Mo Cu Ni Va 0.40 0.15 0.40 0.40 0.08 five elements not to exceed 1% |

| ASTM A 179 ASTM A 214 ASTM A 192 ASTM A 209/T1 ASTM A 209/T1a ASTM A 209/T1B ASTM A 210/A-1 ASTM A 210/C |

MW MW MW MW MW MW MW MW |

0.06-018 0.18MAX 0.06-0.18 0.10-0.20 0.15-0.25 0.14MAX 0.27MAX 0.35MAX |

0.27-0.63 0.27-0.63 0.27-0.63 0.30-0.80 0.30-0.80 0.30-0.80 0.93MAX 0.29-1.06 |

0.048 0.050 0.048 0.045 0.045 0.045 0.048 0.048 |

0.048 0.050 0.048 0.045 0.045 0.045 0.058 0.058 |

- - 0.25MAX 0.10-0.50 0.10-0.50 0.10-0.50 0.10MIN 0.10MIN |

- - - - - - - - |

- - - 0.44-0.65 0.44-0.65 0.44-0.65 - - |

325MIN 385MIN 325MIN 380MIN 365MIN 415MIN 415MIN 485MIN |

180MIN 180MIN 180MIN 205MIN 195MIN 220MIN 255MIN 275MIN |

35.0 35.0 35.0 30/22 30/22 30/22 30/22 30/22 |

Hardness 72 HRB MAX Hardness 72 HRB MAX Hardness 77 HRB MAX Hardness 80 HRB MAX Hardness 81 HRB MAX Hardness 77 HRB MAX Hardness 79 HRB MAX Hardness 89 HRB MAX |

| ASTM A 213/T2 ASTM A 213/T5 ASTM A 213/T11 ASTM A 213/T12 ASTM A 213/T22 |

MW MW MW MW MW |

0.10/0.20 0.15MAX 0.15MAX 0.15MAX 0.15MAX |

0.30-0.61 0.30-0.60 0.30-0.60 0.30-0.61 0.30-0.60 |

0.045 0.030 0.030 0.045 0.030 |

0.045 0.030 0.030 0.045 0.030 |

0.10-0.30 0.50MAX 0.50-1.00 0.50MAX 0.50MAX |

0.50-0.81 4.00-6.00 1.00-1.50 0.80-1.25 1.90-2.60 |

0.44-0.65 0.44-0.65 0.44-0.65 0.44-0.65 0.87-1.13 |

415MIN 415MIN 415MIN 415MIN 415MIN |

205MIN 205MIN 205MIN 220MIN 205MIN |

30/22 30/22 30/22 30/22 30/22 |

Hardness 85 HRB MAX Hardness 85 HRB MAX Hardness 85 HRB MAX Hardness 85 HRB MAX Hardness 85 HRB MAX |

| ASTM A 333/1 ASTM A 333/6 ASTM A 334/1 ASTM A 334/6 |

AW AW AW AW |

0.30MAX 0.30MAX 0.30MAX 0.30MAX |

0.40-1.06 0.29-1.06 0.40-1.06 0.29-1.06 |

0.025 0.025 0.025 0.025 |

0.025 0.025 0.025 0.025 |

- 0.10MIN - 0.10MIN |

- - - - |

- - - - |

380MIN 415MIN 380MIN 415MIN |

205MIN 240MIN 205MIN 240MIN |

25/20 30/22 35/28 30/22 |

Impact AS-50F FOR 40X10J/18/14 -50F 40X10J/18/14 90 HRB MAX |

| ASTM A 335/P1 ASTM A 335/P2 ASTM A 335/P5 ASTM A 335/P9 ASTM A 335/P11 ASTM A 335/P12 ASTM A 335/P22 |

AW AW AW AW AW AW AW |

0.10-0.20 0.10-0.20 0.15MAX 0.15MAX 0.15MAX 0.15MAX 0.15MAX |

0.30-0.80 0.30-0.61 0.30-0.60 0.30-0.60 0.30-0.60 0.30-0.61 0.30-0.60 |

0.025 0.025 0.025 0.025 0.025 0.025 0.025 |

0.025 0.025 0.025 0.025 0.025 0.025 0.025 |

0.10-0.50 0.10-0.30 0.50MAX 0.25-1.00 0.50-1.00 0.50MAX 0.50MAX |

- 0.50-0.81 4.00-6.00 8.00-10.00 1.00-1.50 0.80-1.25 1.90-2.60 |

0.44-0.65 0.44-0.65 0.45-0.65 0.09-1.10 0.44-0.65 0.44-0.65 0.87-1.13 |

380MIN 380MIN 415MIN 415MIN 415MIN 415MIN 415MIN |

205MIN 205MIN 205MIN 172MIN 205MIN 205MIN 205MIN |

30/22 30/22 30/22 30/22 30/22 50/22 30/22 |

|

| BS/3059/1/33 BS/3059/2/33 BS/3059/2/45 BS/3059/2/620 |

0.15MAX 0.15MAX 0.12-0.18 0.10-0.15 |

0.30-0.70 0.40-0.70 0.90-1.20 0.40-0.70 |

0.050 0.050 0.035 0.040 |

0.050 0.050 0.035 0.040 |

- 0.10-0.35 0.10-0.35 0.10-0.35 |

- - - 0.70-1.10 |

- - - 0.45-0.65 |

324-441 324-441 441-560 441-618 |

186MIN 186MIN 245MIN 235MIN |

25 21 22 22 |

||

| DIN/17175/ST35.8 DIN/17175/ST45.8 DIN/17175/15MO3 DIN/17175/13CrMO44 DIN/17175/10CrM910 |

0.17MAX 0.22MAX 0.12-0.20 0.10-0.18 0.15MAX |

0.40MIN 0.45MIN 0.50-0.80 0.40-0.70 0.40-0.60 |

0.040 0.040 0.040 0.040 0.040 |

0.040 0.040 0.040 0.040 0.040 |

0.35MAX 0.10-0.35 0.10-0.35 0.10-0.35 0.15-0.50 |

- - - 0.70-1.60 2.0-2.5 |

- - 0.25-0.35 0.40-0.50 0.9-1.10 |

340-441 441-540 441-540 441-570 441-570 |

235MIN 255MIN 284MIN 294MIN 294MIN |

25 25 21 22 22 |

||

| ASTM A 199/T5 ASTM A 199/T11 ASTM A 199/T22 ASTM A 199/T4 ASTM A 199/T7 ASTM A 200/T5 ASTM A 200/T11 ASTM A 200/T22 ASTM A 200/T4 ASTM A 200/T7 ASTM A 199/T9 |

MW MW MW MW MW MW MW MW MW MW MW |

0.50-0.15 0.50-0.15 0.50-0.15 0.15MAX 0.15MAX 0.15MAX 0.50-0.15 0.50-0.15 0.50-0.15 0.15MAX 0.15MAX |

0.30-0.60 0.30-0.60 0.30-0.60 0.30-0.60 0.30-0.60 0.30-0.60 0.30-0.60 0.30-0.60 0.30-0.60 0.30-0.60 0.30-0.60 |

0.030 0.030 0.030 0.030 0.030 0.030 0.030 0.030 0.030 0.030 0.030 |

0.030 0.030 0.030 0.030 0.030 0.030 0.030 0.030 0.030 0.030 0.030 |

0.50MAX 0.50-1.00 0.50MAX 0.50-1.00 0.50-1.00 0.50-1.00 0.50-1.00 0.50MAX 0.50-1.00 0.50-1.00 0.25-1.00 |

4.00-6.00 1.00-1.50 1.90-2.60 2.15-2.85 6.00-8.00 4.00-6.00 1.00-1.50 1.90-2.60 2.15-2.85 6.00-8.00 8.00-10.0 |

0.45-0.65 0.44-0.65 0.87-1.13 0.44-0.65 0.45-0.65 0.45-0.65 0.44-0.65 0.87-1.13 0.44-0.65 0.45-0.65 0.90-1.10 |

415MIN 415MIN 415MIN 415MIN 415MIN 415MIN 415MIN 415MIN 415MIN 415MIN 415MIN |

170MIN 170MIN 170MIN 170MIN 170MIN 170MIN 170MIN 170MIN 170MIN 170MIN 170MIN |

30/22 30/22 30/22 30/22 30/22 30/22 30/22 30/22 30/22 30/22 30/22 |

Hardness 85 HRB MAX Hardness 85 HRB MAX Hardness 85 HRB MAX Hardness 85 HRB MAX Hardness 85 HRB MAX Hardness 85 HRB MAX Hardness 85 HRB MAX Hardness 85 HRB MAX Hardness 85 HRB MAX Hardness 85 HRB MAX Hardness 85 HRB MAX |

Specification of Alloy Steel Pipes

Specifications governing Alloy Steel Pipe & Tubes are as under:

| Pipes | Tubes |

|---|---|

| ASTM A 335 Grade P - 11 | ASTM 213 Grade T - 11 |

| ASTM A 335 Grade P - 12 | ASTM 213 Grade T - 12 |

| ASTM A 335 Grade P - 22 | ASTM 213 Grade T - 22 |

| ASTM A 335 Grade P - 9 | ASTM 213 Grade T - 9 |

| ASTM A 335 Grade P - 9 A | ASTM 213 Grade T - 9 A |

| ASTM A 335 Grade P - 5 | ASTM 213 Grade T - 5 |

| BS 3604 Grade 620 - 440 | BS 3059 Grade 620 - 460 |

| BS 3604 Grade 621 | |

| BS 3604 Grade 622 | BS 3059 Grade 622 - 490 |

| BS 3604 Grade 625 | |

| BS 3604 Grade 629 - 470 | BS 3059 Grade 629 - 470 |

| BS 3604 Grade 629 - 590 | BS 3059 Grade 629 - 590 |

| BS 3604 Grade 660 | |

| BS 3604 Grade 762 | BS 3059 Grade 762 |

| BS 3059 Grade 243 | |

| ASTM 213 Grade T - 2 | |

| ASTM 213 Grade T - 1 B | |

| DIN 17175 10 Cr Mo 910 | |

| DIN 17175 13 Cr Mo 44 | |

| DIN 17175 X 20 Cr Mo V 121 | |

| ASTM 213 Grade T - 1 | |

| DIN 17175 15 Mo 3 | |

| DIN 17175 14 Mo V 63 |

Chemical properties of Nickel alloys

CHEMICAL PROPERTIES NICKEL ALLOY:

| BRAND® | UNS No | Ni | Co | Mo | C | Cr | V | W | Al | Cu | Nb | Ti | Fe | Others |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Hastelloy-A | 57 | ~ | 21 | 1.0* | ~ | ~ | ~ | ~ | ~ | 19 | ~ | |||

| Hestelloy-B | 62 | 2.5* | 28 | 1.0* | ~ | ~ | ~ | ~ | ~ | 5.5 | 0.4V | |||

| Hestelloy-B2 | N10665 | 66 | 0.75* | 28 | 1.0* | ~ | 0.4* | ~ | ~ | ~ | 2.0* | ~ | ||

| Hestelloy-C | N10002 | rest/bal | 1.25 | 17 | 0.07 | 16 | 0.3 | 40 | - | - | - | - | 5.75 | Mn 1.0 :Si 0 0.70 |

| Hestelloy-C22 | 54 | 2.5* | 14 | 21 | 3 | 0.4* | ~ | ~ | ~ | 5.0* | 0.35*V | |||

| Hestelloy-C276 | N10276 | 56 | 2.5* | 17 | 16 | 4 | 0.4* | ~ | ~ | ~ | 2.5 | 0.35*V | ||

| Hestelloy-C4 | N06455 | 54 | 1.25* | 16 | 16 | ~ | 0.4* | ~ | ~ | 0.5* | 2.0* | ~ | ||

| Hestelloy-D | 85 | ~ | ~ | 1.0* | ~ | ~ | 4.0* | ~ | ~ | 1.0* | 9 si | |||

| Hestelloy-F | 45 | 2.5* | 6 | 22 | 1.0* | ~ | ~ | 2 | ~ | 18 | ~ | |||

| Hestelloy-G | N06007 | 44 | ~ | 6.5 | 22 | 1.0* | ~ | 2 | 2 | ~ | 20 | ~ | ||

| Hestelloy-G2 | 47.0-52.0 | - | 5.0-7.0 | 0.03 | 23.0-26.0 | - | - | - | 0.70-1.20 | - | 0.70-1.50 | rest/bal | Mn 1.0;Si 1.0 | |

| Hestelloy-G3 | N06985 | |||||||||||||

| Hestelloy-N | N10003 | 72 | 0.2 | 16.5 | 7 | 0.5 | 0.25 | ~ | ~ | 0.25 | 5.0* | 0.01 B | ||

| Hestelloy-R | 66 | 1.5* | 5 | 15.5 | ~ | 2.2 | ~ | ~ | 2.5 | 7.0* | ~ | |||

| Hestelloy-S | N06635 | 68 | ~ | 14.5 | 15.5 | ~ | ~ | ~ | ~ | ~ | 1 | 0.5 Mn | ||

| 0.4 Si | ||||||||||||||

| Hestelloy-W | N10004 | 63 | 2.5* | 24.5 | 5 | ~ | ~ | ~ | ~ | ~ | 5.5 | 0.6 V | ||

| Hestelloy-X | N06002 | 47 | 1.5 | 9 | 22 | 0.6 | ~ | ~ | ~ | ~ | 18.5 | ~ | ||

| Inco alloy A-286 | S66286 | 25.5 | 1.5 | 15 | 2.1 | 56 | ||||||||

| Inco alloy C-276 | N10276 | 57 | 16 | 15.5 | 3.8 | 5.5 | ||||||||

| Incoloy-330 | N08330 | |||||||||||||

| Incoloy-600 | N06600 | 75 | - | - | 0.05 | 15.5 | - | - | - | - | - | - | 8 | - |

| Incoloy-601 | N06601 | 60 | - | - | 0.05 | 23 | - | - | 1.4 | - | - | - | 14 | - |

| Incoloy-604 | rest/bal | - | - | 0.04 | 15.8 | - | - | - | 0.1 | Nb 2.0 | - | 7.2 | Mn 0.20; Si 0.20 | |

| Incoloy-610 | rest/bal | - | - | 0.2 | 15.5 | - | - | - | 0.5 | Nb 1.0 | - | 9 | Mn 0.90;Si 2.0 | |

| Incoloy-617 | N06617 | 54 | 12.5 | 9 | 0.07 | 22.5 | - | - | 1 | - | - | - | - | - |

| Incoloy-625 | N06625 | 61 | - | 9 | 0.05 | 21.5 | - | - | 0.4 | - | Nb 3.65 | 0.4 | 2.5 | Mn 0.50; Si 0.50 |

| Incoloy-671 | 51 | - | - | 0.05 | 48 | - | - | - | - | - | 0.35 | - | - | |

| Incoloy-700 | 46 | 28.5 | 3.75 | 0.12 | 15 | - | - | 3 | 0.05 | - | 2.2 | 0.7 | Mn 0.10; Si 0.30 | |

| Incoloy-702 | rest/bal | - | - | 0.04 | 15.6 | - | - | 3.4 | 0.1 | - | 0.7 | 0.35 | Mn 0.05: Si 0.20 | |

| Incoloy-705 | rest/bal | - | - | 0.3 | 15.5 | - | - | - | 0.5 | - | - | 8 | Mn 0.90 ; Si 5.5 | |

| Incoloy-800 | N08800 | 32 | ~ | ~ | 20 | ~ | ~ | ~ | ~ | ~ | 47 | ~ | ||

| Incoloy-800H | 32 | - | - | 0.08 | 21 | - | - | 0.3 | - | - | 0.4 | 45 | - | |

| Incoloy-801 | N08801 | 32 | - | - | 0.05 | 20.5 | - | - | - | - | - | 1.1 | 45 | - |

| Incoloy-802 | 32 | - | - | 0.35 | 21 | - | - | 0.6 | - | - | 0.7 | 45 | - | |

| Incoloy-804 | 41 | - | - | 0.05 | 29.5 | - | - | 0.3 | - | - | 0.6 | 25.4 | - | |

| Incoloy-805 | 36 | - | 0.5 | 0.12 | 7.5 | - | - | - | 0.1 | - | - | rest/bal | Mn 0.60;Si 0.50 | |

| Incoloy-810 | 32 | - | - | 0.25 | 21 | - | - | - | 0.5 | - | - | rest/bal | Mn 0.90; Si 0.80 | |

| Incoloy-825 | N08825 | 40 | ~ | 3 | 0.04 | 21 | ~ | ~ | 2 | ~ | 1 | 32 | ~ | |

| Incoloy-825CP | 42 | - | 3 | 0.04 | 21.5 | - | - | - | 2.2 | Nb0.9 | - | 30 | - | |

| Incoloy-840 | 20 | - | - | 0.08 | 20 | - | - | - | - | - | - | rest/bal | Mn 1.0;Si 1.0 | |

| Incoloy-901 | 42 | 1.0* | 5.7 | 0.05 | 12.5 | ~ | 0.35* | ~ | ~ | 2.9 | 35 | ~ | ||

| Incoloy-901Mod | rest/bal | - | 5.8 | 0.05 | 12.5 | - | - | - | - | - | 2.9 | 34 | Mn 0.09;Si 0.08;B0.015 | |

| Incoloy-903 | 38 | 15 | - | 0.02 | - | - | - | 0.7 | - | Nb 3.0 | 1.4 | 41 | - | |

| Incoloy-904 | 33 | 14 | - | 0.02 | - | - | - | - | - | - | 1.7 | 50 | - | |

| Incoloy-925 | 42 | 3 | 21 | 2.2 | 2.1 | 32 | ||||||||

| Incoloy-DS | 37 | - | - | 0.06 | 18 | - | - | - | - | - | - | 42 | Mn 1.0; Si 2.3 | |

| Incoloy-ma 956 | - | - | - | - | 20 | - | - | 4.5 | - | - | 0.5 | 74.4 | Y2.03 0.5 | |

| Inconel-600 | N06600 | 75.5 | ~ | ~ | 15.5 | ~ | ~ | ~ | ~ | ~ | 7 | ~ | ||

| Inconel-601 | N06601 | 60.5 | ~ | ~ | 23 | ~ | 1.35 | ~ | ~ | ~ | 14.1 | ~ | ||

| Inconel-617 | N06617 | 52 | 12.5 | 9 | 22 | 1.2 | ||||||||

| Inconel-625 | N06625 | 61 | ~ | 9 | 21.5 | ~ | ~ | ~ | 3 | ~ | 3 | ~ | ||

| Inconel-690 | N06690 | 61 | ~ | ~ | 29 | ~ | ~ | ~ | ~ | ~ | 9 | ~ | ||

| Inconel-702 | 79 | ~ | ~ | 15.6 | ~ | 3.4 | ~ | ~ | 0.7 | 0.4 | ~ | |||

| Inconel-706 | 41.5 | 1 | ~ | 16 | ~ | ~ | ~ | 2.9 | 17.5 | 36 | ~ | |||

| Inconel-713C | 72 | ~ | 4.5 | 13.4 | ~ | 6.2 | ~ | 2.3 | 1.0* | 1.5* | ~ | |||

| Inconel-718 | N07718 | 53 | ~ | 3 | 18.5 | ~ | ~ | ~ | 5 | 0.8 | 18 | ~ | ||

| Inconel-X(X750) | N07750 | 73 | 1 | ~ | 15 | ~ | 0.9 | ~ | ~ | 2.5 | 7 | ~ | ||

| Inconel-W(722) | 75 | ~ | ~ | 15 | ~ | 0.6 | ~ | ~ | 2.4 | 6.5 | ~ | |||

| Invar-42 | ||||||||||||||

| GMR 235 | 63 | ~ | 5.2 | 15.5 | ~ | 3.7 | ~ | ~ | 2 | 10 | 0.06 B | |||

| IN-657 | 49 | ~ | ~ | 48 | ~ | ~ | ~ | 1.5 | ~ | ~ | ~ | |||

| Monel-400 | N04400 | 65 | - | - | 0.12 | - | - | - |

Product Specification of Nickel Alloys

(ASTM) standards for stainless steels for general applications

American (ASTM) standards for stainless steels for general applications:

| Std Number | Title |

|---|---|

| General | |

| ASTM A450 | Specification for General Requirements for Carbon, Ferritic Alloy, and Austenitic Alloy Steel Tubes |

| ASTM A480 | Specification for General Requirements for Flat-Rolled Stainless And Heat-Resisting Steel Plate, Sheet and Strip |

| ASTM A484 | Specification for General Requirements for Stainless Steel Bars, Billets, and Forgings |

| ASTM A555 | Specification for General Requirements for Stainless Steel Wire and Wire Rods |

| ASTM A999 | Specification for General Requirements for Alloy and Stainless Steel Pipe |

| ASTM A1016 | Specification for General Requirements for Ferritic Alloy Steel, Austenitic Alloy Steel and Stainless Steel Tubes |

| Flat Products | |

| ASTM A167 | Specification for Stainless and Heat-Resisting Chromium-Nickel Steel Plate, Sheet and Strip |

| ASTM A176 | Specification for Stainless and Heat-Resisting Chromium Steel Plate, Sheet, and Strip |

| ASTM A666 | Specification For Annealed or Cold-Worked Austenitic Stainless Steel Sheet, Strip, Plate and Flat Bar |

| ASTM A693 | Specification for Precipitation-Hardening Stainless And Heat-Resisting Steel Plate, Sheet and Strip |

| Long Products | |

| ASTM A276 | Specification for Stainless Steel Bars and Shapes |

| ASTM A314 | Specification for Stainless Steel Billets and Bars for Forging |

| ASTM A493 | Specification for Stainless Steel Wire and Wire Rods for Cold Heading and Cold Forging |

| ASTM A564 | Specification for Hot-Rolled And Cold-Finished Age-Hardening Stainless Steel Bars and Shapes |

| ASTM A565 | Specification for Martensitic Stainless Steel Bars, Forgings, and Forging Stock for High Temperature Service |

| ASTM A582 | Specification for Free Machining Stainless Steel Bars |

| Forgings | |

| ASTM A473 | Specification for Stainless Steel Forgings |

| ASTM A705 | Specification for Age Hardening Stainless and Heat Resisting Steel Forgings |

| Castings | |

| ASTM A297 | Specification for Steel Castings, Iron-Chromium and Iron-Chromium-Nickel, Heat-Resistant for General Application |

| ASTM A743 | Standard Specification for Castings, Iron-Chromium, Iron-Chromium-Nickel, Corrosion Resistant, for General Application |

| ASTM A744 | Standard Specification for Castings, Iron-Chromium-Nickel, Corrosion Resistant, for Severe Service |

| ASTM A890 | Standard Specification for castings, iron-chromium-nickel-molybdenum corrosion-resistant, duplex (austenitic/ferritic) for general application |

| Pipes | |

| ASTM A312 / A312M | Seamless and Welded Austenitic Stainless Steel Pipe |

| ASTM A358 / A358M | Electric-Fusion-Welded (EFW) Austenitic Chromium-Nickel Alloy Steel Pipe for High Temperature Service |

| ASTM A409 / A409M | Welded Large Diameter Austenitic Steel Pipe for Corrosive or High Temperature Service |

| ASTM A731 / A731M | Seamless and Welded Ferritic and Martensitic Stainless Steel Pipe |

| ASTM A790 / A790M | Seamless and Welded Ferritic / Austenitic Stainless Steel Pipe |

| ASTM A450 / A450M | General Requirements for Carbon, Ferritic Alloy and Austenitic Steel Tubes |

| ASTM A530 / A530M | General Requirements for Specialised Carbon and Alloy Steel Pipe |

| JIS G3459 | Stainless Steel Pipes |

| Higher Austenitic | |

| ASTM B673 | UNS N08904 UNS N08925 and UNS N08926 Welded Pipe |

| ASTM B677 | UNS N08904 UNS N08925 and UNS N08926 Seamless Pipe and Tube |

| ASTM A268 | Specification for Seamless and Welded Ferritic Stainless Steel Tubing for General Service |

| ASTM A511 | Specification for Seamless Stainless Steel Mechanical Tubing |

| ASTM A632 | Specification for Seamless and Welded Austenitic Stainless Steel Tubing (Small-Diameter) for General Service |

| ASTM A789 | Specification for Seamless and Welded Ferritic/Austenitic Stainless Steel Tubing for General Service |

| Pipe Fittings & Flanges | |

| ASTM A182 / A182M | Forged or Rolled Alloy Steel Pipe Flanges, Forged Fittings and Values and Parts for High Temperature Service |

| ASTM A403 / A403M | Wrought Austenitic Stainless Steel Piping Fittings |

| ASTM A530 / A530M | General Requirements for Specialised Carbon and Alloy Steel Pipe |

| ASTM A815 / A815M | Wrought Ferritic, Ferritic / Austenitic and Martensitic Stainless Steel Piping Fittings |

| ASTM A276 | Stainless and Heat Resisting Steel Bars and Shapes |

| ASTM A351 / A351M | Steel Castings, Austenitic, for High Temperature Service |

| AS 2129 | Flanges for Pipes, Values and Fittings |

| ANSI / ASME B 1.20.1 | Pipe threads, general purpose (inch) |

| ANSI B 16.3 | Malleable iron threaded fittings |

| ANSI B 16.5 | Steel pipe flanges and flanged fittings |

| ANSI B 16.9 | Factory made wrought steel butt welding fittings |

| ANSI B 16.11 | Forged steel fittings wocket-welding and threaded |

| ANSI B 16.25 | Butt-welding ends |

| ANSI B 16.28 | Wrought steel butt welding short radius elbows and returns |

| Tube & Tube Fittings | |

| ASTM A213 / A213M | Seamless Ferritic and Austenitic Alloy Steel Boiler, Superheater and Heat Exchanger Tubes |

| ASTM A249 / A249M | Welded Austenitic Steel Boiler, Superheater, Heat Exchanger and Condenser Tubes |

| ASTM A269 | Seamless and Welded Austenitic Stainless Steel Tubing for General Service |

| ASTM A270 | Seamless and Welded Austenitic Stainless Steel Sanitary Tubing |

| ASTM A450 / A450M | General Requirements for Carbon, Ferritic Alloy, and Austenitic Alloy Steel Tubes |

| ASTM A554 | Welded Stainless Steel Mechanical Tubing |

| ASTM A791 / A791M | Welded Unannealed Ferritic Stainless Steel Tubing |

| ASTM A789 / A789M | Seamless and Welded Ferritic / Austenitic Stainless Steel Tubing for General Service |

| AS 1163 | Structural Steel Hollow Sections (Dimensional Tolerances) |

| AS 1528 | Tubes (Stainless Steel) and Tube Fittings for the Food Industry. |

| ASTM B674 | UNS N08904 UNS N08925 and UNS N08926 Welded Pipe |

| ASTM B677 | UNS N08904 UNS N08925 and UNS N08926 Seamless Pipe and Tube |

| ASTM A790 | Specification for Seamless and Welded Ferritic/Austenitic Stainless Steel Pipe |

| ASTM A813 | Specification for Single or Double Welded Austenitic Stainless Steel Pipe |

| ASTM A814 | Specification for Cold Worked Welded Austenitic Stainless Steel Pipe |

Copper Alloys

COPPER ALLOYS:

| Copper or Copper Alloy Product | ASTM Spec |

|---|---|

| Hard drawn copper wire | B1 |

| Medium hard drawn copper wire | B2 |

| Annealed copper wire | B3 |

| Bronze trolley wire | B9 |

| Free cutting brass rod, bar, and shapes for use in screw machines | B16 |

| Cartridge brass sheet, strip, plate, bar, and disks | B19 |

| Naval brass rod, bar, and shapes | B22 |

| Bronze castings for bridges and turntables | B22 |

| Copper alloy ingots | B30 |

| Tinned soft or annealed copper electrical wire | B33 |

| Standard sized seamless copper pipe | B43 |

| Copper trolley wire | B47 |

| Annealed rectangular and square bare copper electrical wire | B48 |

| Hot rolled copper rod redraw for electrical use | B49 |

| Steam or valve bronze castings | B61 |

| Bronze rough castings for locomotive wear parts | B66 |

| Car and tender lined journal bearings | B67 |

| Seamless bright annealed copper tube | B68 |

| Seamless copper tube | B75 |

| Seamless copper water tube | B88 |

| General purpose and pressure vessel Cu-Si alloy plate, sheet, strip, and rolled bar | B96 |

| Cu-Si alloy rod, bar, and shapes | B98 |

| General purpose Cu-Si alloy wire | B99 |

| Rolled copper alloy bearing and expansion plates and sheets for bridges and structural use | B100 |

| Lead coated copper sheet | B101 |

| Phosphor bronze plate, sheet, strip, and rolled bar | B103 |

| Hard drawn copper alloy wires for electrical conductors | B105 |

| Copper and copper alloy seamless condenser tubes and ferrule stock | B111 |

| Fig. 9 deep section grooved and fig. 8 Cur trolley wire for industrial haulage | B116 |

| Leaded brass plate, sheet, strip, and rolled bar | B121 |

| Copper and copper alloy forging rod, bar, and shapes | B124 |

| Cartridge brass cartridge case cups | B129 |

| Commercial bronze strip for bullet jackets | B130 |

| Copper alloy bullet jacket cups | B131 |

| Copper rod, bar, and shapes | B133 |

| Brass wire | B134 |

| Seamless brass tube | B135 |

| Manganese bronze rod, bar, and shapes | B138 |

| Phosphor bronze rod, bar, and shapes | B139 |

| Leaded red brass hardware bronze rod, bar, and shapes | B140 |

| Aluminum bronze sand castings | B148 |

| Aluminum bronze rod, bar, and shapes | B150 |

| Nickel Silver (Cu-Ni-Zn) and Cu-Ni rod and bar | B151 |

| Copper sheet, strip, plate, and rolled bar | B152 |

| Phosphor bronze wire | B159 |

| Aluminum bronze, plate, sheet, strip, and rolled bar | B169 |

| Copper alloy condenser tube plates | B171 |

| Rope lay std. conductors w/ bunch stranded members | B172 |

| Rope lay std. conductors w/ concentric stranded members | B173 |

| Bunch stranded conductors | B174 |

| Brass die castings | B176 |

| Copper bus bar, rod, and shapes | B187 |

| Seamless copper bus pipe and tube | B188 |

| Lead copper and Lead copper alloy coated soft copper electrical wire | B189 |

| Beryllium Copper (Cu-Be) alloy plate, sheet, strip, and rolled bar | B194 |

| Beryllium Copper (Cu-Be) alloy rod and bar | B196 |

| Beryllium Copper (Cu-Be) alloy wire | B197 |

| Nickel Silver (Cu-Ni-Zn) and Cu-Ni alloy wire | B206 |

| Cored, annular, concentric-lay stranded copper conductors | B226 |

| Concentric-lay stranded copper and copper clad steel conductors | B229 |

| Tinned hard drawn and medium hard drawn copper electrical wire | B246 |

| Copper base alloy centrifugal castings | B271 |

| Copper flat wire and strip w/rolled or drawn edges | B272 |

| Seamless copper tube for air conditioning and refrigerator use | B280 |

| Copper and copper alloy hot pressed die forgings | B283 |

| Copper conductors for electronic equipment wire hookups | B286 |

| Manganese brass (Cu-Zn-Mn) sheet and strip | B291 |

| Silver coated annealed copper wire | B298 |

| Free cutting copper rod and bar | B301 |

| Threadless copper pipe | B302 |

| Copper drainage tube (DWV) | B306 |

| Seamless copper alloy pipe and tube | B315 |

| Nickel coated annealed copper wire | B355 |

| Copper and copper alloy seamless condenser and heat exchanger tubes with fins | B359 |

| Hard drawn copper capillary tube for restrictor applications | B360 |

| Cu-Ni alloy castings | B369 |

| Copper sheet and strip for building construction | B370 |

| Cu-Zinc-Si alloy rod | B371 |

| Seamless copper and copper alloy rectangular wave guide tube | B372 |

| U-bend seamless copper and copper alloy heat exchanger and condenser tubes | B395 |

| Cu-Ni-Si alloy rod and bar | B411 |

| Cu-Ni-Si alloy wire | B412 |

| Cu-Al-Si-Co alloy and Cu-Ni-Al-Si alloy sheet and strip | B422 |

| Gear bronze castings | B427 |

| Copper and copper alloy clad steel plate | B432 |

| Cu-Co-Be (UNS C17500) and Cu-Ni-Be (UNS C17510) rod and bar | B441 |

| Welded copper tube | B447 |

| Copper foil, strip and sheet for printed circuits and carrier tapes | B451 |

| Leaded brass (Cu-Zn-Pb) rod | B453 |

| Leaded brass (Cu-Zn-Pb) extruded shapes | B455 |

| Cu-Fe alloy plate, sheet, strip, and rolled bar | B465 |

| Seamless Cu-Ni pipe and tube | B466 |

| Welded Cu-Ni pipe | B467 |

| Seamless Cu-Ni pipe and tube | B469 |

| Bonded copper conductors for use in hookup wire for electronic equipment | B470 |

| Cast Cu-Ni ship tailshaft sleeves | B492 |

| Compact round concentric-lay-stranded copper conductors | B496 |

| Copper alloy continuous castings | B505 |

| Copper clad stainless steel sheet and strip for building construction | B506 |

| Copper alloy strip for flexible metal hose | B508 |

| Cu-Co-Be alloy, plate, sheet, strip, and rolled bar | B534 |

| Welded copper and copper alloy heat exchanger tube | B543 |

| Seamless and welded Cu-Ni tubes for water desalination plants | B552 |

| Light gauge UNS C26000 brass strip in narrow widths for heat exchanger tubing | B569 |

| Beryllium Copper (Cu-Be) alloy forgings and extrusions | B570 |

| General purpose copper alloy sand castings | B584 |

| Welded brass tube | B587 |

| Cu-Zn-Sn alloy plate, sheet, strip, and rolled bar | B591 |

| Cu-Zn-Al-Co alloy plate, sheet, strip, and rolled bar | B592 |

| Welded copper alloy pipe | B608 |

| High-strength, high-conductivity copper alloy electronic wire | B624 |

| Copper and copper alloy solar heat absorber panels | B638 |

| Welded copper and copper alloy tube for AC or refrigeration use | B640 |

| Seamless and type D welded copper distribution tube | B641 |

| Beryllium Copper (Cu-Be) alloy seamless tube | B643 |

| Brass, Cu, and Cr plated pipe nipples | B687 |

| Cu, copper alloy, and Cu-clad stainless steel sheet and strip for electrical cable shielding | B694 |

| UNS C69100 seamless copper alloy pipe and tube | B706 |

| Welded copper water tube | B716 |

| Fine wire and rope-lay bunch stranded copper electrical conductors | B738 |

| Cu-Ni-Sn spinodal alloy strip | B740 |

| Seamless copper tube coils | B743 |

| Cu-Zn alloy sheet and strip | B747 |

| Sand cast copper alloy for valve applications | B743 |

| Cu-Co-Be alloy sheet and strip | B768 |

| Round wire for use as grid side rods in electron tubes | F9 |

| Wrought oxygen-free copper for electronic devices | F68 |

| Wrought electronic grade copper alloys | F96 |

| General use nonferrous nuts | F467 |

| General use nonferrous bolts, hex cap screws, and studs | F468 |

Pipe Data

NOMINAL THICKNESS AND WEIGHTS OF STAINLSS STEEL PIPES (ANSI B 36.10):

| Nominal pipe size |

OD | Schedule 10 |

Schedule 20 |

Schedule 30 |

Schedule Standard |

Schedule 40 |

Schedule 60 |

Schedule XS |

Schedule 80 |

Schedule 100 |

Schedule 120 |

Schedule 140 |

Schedule 160 |

Schedule XXS |

||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | inch | mm | Wall | kg/m | Wall | kg/m | Wall | kg/m | Wall | kg/m | Wall | kg/m | Wall | kg/m | Wall | kg/m | Wall | kg/m | Wall | kg/m | Wall | kg/m | Wall | kg/m | Wall | kg/m | Wall | kg/m |

| 3 | 1/8 | 10.3 | 1.7 | 0.357 | 1.7 | 0.357 | 2.4 | 0.470 | 2.4 | 0.470 | ||||||||||||||||||

| 6 | 1/4 | 13.7 | 2.2 | 0.625 | 2.2 | 0.625 | 3.0 | 0.804 | 3.0 | 0.804 | ||||||||||||||||||

| 10 | 3/8 | 17.1 | 2.3 | 0.848 | 2.3 | 0.848 | 3.2 | 1.10 | 3.2 | 1.10 | ||||||||||||||||||

| 15 | 1/2 | 21.3 | 2.8 | 1.26 | 2.8 | 1.26 | 3.7 | 1.62 | 3.7 | 1.62 | 4.8 | 1.95 | 7.5 | 2.54 | ||||||||||||||

| 20 | 3/4 | 26.7 | 2.9 | 1.68 | 2.9 | 1.68 | 3.9 | 2.19 | 3.9 | 2.19 | 5.6 | 2.89 | 7.8 | 3.63 | ||||||||||||||

| 25 | 1 | 33.4 | 3.4 | 2.50 | 3.4 | 2.50 | 4.5 | 3.23 | 4.5 | 3.23 | 6.4 | 4.23 | 9.1 | 5.45 | ||||||||||||||

| 32 | 11/4 | 44.2 | 3.6 | 3.38 | 3.6 | 3.38 | 4.8 | 4.47 | 4.8 | 4.47 | 6.4 | 5.60 | 9.7 | 7.97 | ||||||||||||||

| 40 | 11/2 | 48.3 | 3.7 | 4.05 | 3.7 | 4.05 | 5.1 | 5.40 | 5.1 | 5.40 | 7.1 | 7.23 | 10.2 | 9.58 | ||||||||||||||

| 50 | 2 | 60.3 | 3.9 | 5.3 | 3.9 | 5.3 | 5.5 | 7.47 | 5.5 | 7.47 | 8.7 | 11.1 | 11.1 | 13.4 | ||||||||||||||

| 65 | 22/2 | 73.0 | 5.2 | 8.62 | 5.2 | 8.62 | 7.0 | 11.4 | 7.0 | 11.4 | 9.5 | 14.9 | 14.0 | 20.4 | ||||||||||||||

| 80 | 3 | 88.9 | 5.5 | 11.3 | 5.5 | 11.3 | 7.6 | 15.3 | 7.6 | 15.3 | 11.1 | 21.3 | 15.2 | 27.7 | ||||||||||||||

| 90 | 31/2 | 101.6 | 5.7 | 13.6 | 5.7 | 13.6 | 8.1 | 18.6 | 8.1 | 18.6 | 16.2 | 34.1 | ||||||||||||||||

| 100 | 4 | 114.3 | 6.0 | 16.1 | 6.0 | 16.1 | 8.6 | 22.3 | 8.6 | 22.3 | 11.1 | 28.3 | 13.5 | 33.5 | 17.1 | 41.1 | ||||||||||||

| 125 | 5 | 141.3 | 6.6 | 21.8 | 6.6 | 21.8 | 9.5 | 30.9 | 9.5 | 30.9 | 12.7 | 40.2 | 15.9 | 49.0 | 19.0 | 57.4 | ||||||||||||

| 150 | 6 | 168.3 | 7.1 | 28.2 | 7.1 | 28.2 | 11.0 | 42.5 | 11.0 | 42.5 | 14.3 | 54.2 | 18.3 | 67.5 | 21.9 | 79.1 | ||||||||||||

| 200 | 8 | 219.1 | 6.4 | 33.3 | 7.0 | 36.7 | 8.2 | 42.5 | 8.2 | 42.5 | 10.3 | 53.1 | 12.7 | 64.6 | 12.7 | 64.6 | 151.1 | 75.8 | 18.3 | 90.4 | 20.6 | 101 | 23.0 | 112.0 | 22.2 | 108.0 | ||

| 250 | 10 | 273.0 | 6.4 | 41.7 | 7.8 | 50.9 | 9.3 | 60.2 | 9.3 | 60.2 | 12.7 | 81.5 | 12.7 | 81.5 | 15.1 | 95.8 | 18.3 | 114.7 | 21.4 | 132.9 | 25.4 | 155 | 28.6 | 172.2 | 25.4 | 155.0 | ||

| 300 | 12 | 323.8 | 6.4 | 49.7 | 8.4 | 65.1 | 9.5 | 73.8 | 10.3 | 79.7 | 14.3 | 109.0 | 12.7 | 97.4 | 17.4 | 132.0 | 21.4 | 160.0 | 25.4 | 187.0 | 28.6 | 208 | 33.3 | 239.0 | 25.4 | 187.0 | ||

| 350 | 14 | 355.6 | 6.4 | 54.6 | 7.9 | 68.1 | 9.5 | 81.2 | 9.5 | 81.2 | 11.1 | 94.6 | 15.1 | 126.4 | 12.7 | 107.0 | 19.0 | 158.0 | 23.8 | 195.0 | 27.8 | 224.0 | 31.8 | 253 | 35.7 | 281.0 | ||

| 400 | 16 | 406.4 | 6.4 | 62.6 | 7.9 | 77.9 | 9.5 | 93.1 | 9.5 | 93.3 | 12.7 | 123.0 | 16.7 | 160.0 | 12.7 | 123.0 | 21.4 | 203.0 | 26.2 | 245.0 | 30.9 | 286.0 | 36.5 | 333 | 40.5 | 365.0 | ||

| 450 | 18 | 457.2 | 6.4 | 70.5 | 7.9 | 87.8 | 11.1 | 122.0 | 9.5 | 105.0 | 14.3 | 156.0 | 19.0 | 206.0 | 12.7 | 139.0 | 23.8 | 254.0 | 29.4 | 310.0 | 34.9 | 363.0 | 39.7 | 408 | 45.2 | 459.0 | ||

| 500 | 20 | 508.0 | 6.4 | 78.5 | 9.5 | 117.0 | 12.7 | 155.0 | 9.5 | 117.0 | 15.1 | 183.0 | 20.6 | 248.0 | 12.7 | 155.0 | 26.2 | 311.0 | 32.5 | 381.0 | 38.1 | 441.0 | 44.4 | 508 | 50.0 | 564.0 | ||

| 550 | 22 | 558.8 | 6.4 | 86.4 | 9.5 | 129.0 | 12.7 | 171.0 | 9.5 | 129.0 | 22.2 | 294.0 | 12.7 | 171.0 | 28.6 | 373.0 | 34.9 | 451.0 | 41.3 | 526.0 | 47.6 | 600 | 54.0 | 671.0 | ||||

| 600 | 24 | 609.6 | 6.4 | 94.7 | 9.5 | 141.0 | 14.3 | 210.0 | 9.5 | 141.0 | 17.4 | 255.0 | 24.6 | 355.0 | 12.7 | 187.0 | 30.9 | 441.0 | 38.9 | 547.0 | 45.0 | 639.0 | 52.4 | 719 | 59.5 | 807.0 | ||

| 650 | 26 | 660.4 | 7.9 | 128.0 | 12.7 | 203.0 | 9.5 | 153.0 | 12.7 | 203.0 | ||||||||||||||||||

| 700 | 28 | 711.2 | 7.9 | 137.4 | 12.7 | 219.0 | 15.9 | 272.0 | 9.5 | 165.0 | 12.7 | 219.0 | ||||||||||||||||

| 750 | 30 | 762.0 | 7.9 | 147.0 | 12.7 | 234.6 | 15.9 | 292.6 | 9.5 | 176.0 | 12.7 | 234.6 | ||||||||||||||||

| 800 | 32 | 812.8 | 7.9 | 157.0 | 12.7 | 250.6 | 15.9 | 312.5 | 9.5 | 188.2 | 12.7 | 250.6 | ||||||||||||||||

| 850 | 34 | 863.6 | 7.9 | 167.0 | 12.7 | 266.0 | 15.9 | 332.4 | 9.5 | 200.0 | 12.7 | 266.5 | ||||||||||||||||

| 900 | 36 | 914.4 | 7.9 | 176.6 | 12.7 | 282.4 | 15.9 | 352.2 | 9.5 | 212.0 | 12.7 | 281.4 | ||||||||||||||||

LINE PIPE WEIGHT:

| Nominal Pipe Size |

Outside Diameter | Sch *5 |

Sch *10 |

Sche dule 20 |

Sche dule 30 |

Stan da rd weig ht |

Sched ule 40 |

Extra Str ong |

Sche dule 60 |

Sche dule 80 |

sche dule 100 |

Sche dule 120 |

Sche dule 140 |

Sche dule 160 |

Do uble Ex. Str. |

|

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | in | mm | Kg/m | Kg/m | Kg/m | Kg/m | Kg/m | Kg/m | Kg/m | Kg/m | Kg/m | Kg/m | Kg/m | Kg/m | Kg/m | Kg/m |

| 8 | 1/4 | 13.7 | -- | 0.491 | -- | -- | 0.63 | 0.63 | 0.80 | -- | 0.80 | -- | -- | -- | -- | -- |

| 10 | 3/8 | 17.1 | -- | 0.631 | -- | -- | 0.84 | 0.84 | 1.10 | -- | 1.10 | -- | -- | -- | -- | -- |

| 15 | 1/2 | 21.3 | 0.801 | 0.999 | -- | -- | 1.27 | 1.27 | 1.62 | -- | 1.62 | -- | -- | -- | 1.95 | 2.55 |

| 20 | 3/4 | 26.7 | 1.020 | 1.280 | -- | -- | 1.69 | 1.69 | 2.19 | -- | 2.19 | -- | -- | -- | 2.90 | 3.63 |

| 25 | 1 | 33.4 | 1.290 | 2.090 | -- | -- | 2.50 | 2.50 | 3.23 | -- | 3.23 | -- | -- | -- | 4.23 | 5.45 |

| 32 | 11/4 | 42.2 | 1.650 | 2.69 | -- | -- | 3.38 | 3.38 | 4.47 | -- | 4.47 | -- | -- | -- | 5.60 | 7.76 |

| 40 | 11/2 | 48.3 | 1.900 | 3.11 | -- | -- | 4.05 | 4.05 | 5.41 | -- | 5.41 | -- | -- | -- | 7.24 | 9.55 |

| 50 | 2 | 60.3 | 3.340 | 3.92 | -- | -- | 5.44 | 5.44 | 7.48 | -- | 7.48 | -- | -- | -- | 11.11 | 13.45 |

| 65 | 21/2 | 73.0 | 3.690 | 5.26 | -- | -- | 8.62 | 8.62 | 11.41 | -- | 11.41 | -- | -- | -- | 14.91 | 20.39 |

| 80 | 3 | 88.9 | 4.510 | 6.45 | -- | -- | 11.29 | 11.29 | 15.27 | -- | 15.27 | -- | -- | -- | 21.33 | 27.67 |

| 90 | 31/2 | 101.6 | 5.180 | 7.41 | -- | -- | 13.57 | 13.57 | 18.63 | -- | 18.63 | -- | -- | -- | -- | -- |

| 100 | 4 | 114.3 | 5.940 | 8.38 | -- | -- | 16.07 | 16.07 | 22.31 | -- | 22.31 | -- | 28.30 | -- | 33.53 | 41.02 |

| 125 | 5 | 141.3 | 9.340 | 11.60 | -- | -- | 21.78 | 21.78 | 30.95 | -- | 30.95 | -- | 40.28 | -- | 49.09 | 57.42 |

| 150 | 6 | 168.3 | 11.30 | 13.80 | -- | -- | 28.26 | 28.26 | 42.56 | -- | 42.56 | -- | 54.20 | -- | 67.55 | 79.18 |

| 200 | 8 | 219.1 | 14.80 | 20.00 | 33.31 | 36.79 | 42.53 | 42.53 | 64.63 | 53.09 | 64.63 | 75.89 | 90.43 | 100.93 | 111.25 | 107.87 |

| 350 | 10 | 273.1 | 22.60 | 27.80 | 41.77 | 51.00 | 60.29 | 60.29 | 81.55 | 81.54 | 95.97 | 114.70 | 133.00 | 155.10 | 172.25 | 155.10 |

| 300 | 12 | 323.9 | 31.24 | 35.99 | 49.72 | 65.20 | 73.82 | 79.72 | 97.44 | 108.96 | 132.01 | 159.85 | 186.92 | 208.04 | 238.72 | 186.92 |

| 350 | 14 | 355.6 | 34.34 | 54.68 | 67.94 | 81.28 | 81.28 | 94.49 | 107.38 | 126.68 | 158.08 | 194.90 | 224.60 | 253.53 | 281.68 | -- |

| 400 | 16 | 406.4 | 41.56 | 62.63 | 77.86 | 93.21 | 93.21 | 123.29 | 123.29 | 160.12 | 203.48 | 245.50 | 286.62 | 333.11 | 365.39 | -- |

| 450 | 18 | 457 | 46.80 | 70.59 | 87.79 | 122.36 | 105.14 | 155.91 | 139.19 | 205.80 | 254.59 | 309.76 | 363.65 | 408.45 | 459.51 | -- |

| 500 | 20 | 508 | 59.32 | 78.84 | 177.07 | 155.10 | 117.07 | 183.37 | 155.01 | 247.85 | ||||||

| 550 | 22 | 559 | 65.30 | 86.50 | 129.01 | 171.01 | 129.01 | -- | 171.01 | -- | ||||||

| 600 | 24 | 610 | 82.52 | 94.45 | 140.94 | 209.54 | 140.94 | 255.14 | 186.92 | 355.02 | ||||||

| 650 | 26 | 660 | -- | 127.50 | 202.83 | -- | 152.87 | -- | 202.83 | -- | ||||||

| 700 | 28 | 711 | -- | 137.42 | 218.73 | 272.18 | 164.80 | -- | 218.73 | -- | ||||||

| 750 | 30 | 762 | 118.33 | 147.36 | 234.64 | 292.06 | 176.73 | -- | 236.64 | -- | ||||||

| 800 | 32 | 813 | -- | 152.28 | 250.55 | 311.95 | 188.66 | 342.70 | 250.55 | -- | ||||||

| 850 | 34 | 864 | -- | 167.20 | 266.46 | 331.83 | 200.59 | 364.58 | 266.46 | -- | ||||||

| 900 | 36 | 914 | -- | 177.13 | 282.36 | 351.72 | 212.52 | 420.52 | 282.36 | -- | ||||||

TUBES & PIPES:

| Nominal Pipe Size |

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Specification Chart of Tubes & Pipes | ||||||||||

| CHEMICAL COMPOSITION CS :- Carbon Steel |

Mechanical Propent-size: 8pt | |||||||||

| Tensile Strength | Yield stress | Elongation In | ||||||||

| Specification | WT | Type | C% | Mn% MAX | P% MI | S% | Si% | Mpa | Mpa | 50mm MIN Longitudinal |

| ASTM A179 | M/W | CS | 0.06-0.18 | 0.27-0.63 | 0.048 | 0.058 | -- | -- | -- | -- |

| ASTM A192 | M/W | CS | 0.06-0.18 | 0.27-0.63 | 0.048 | 0.058 | 0.25 MAX | -- | -- | -- |

| ASTM A210/ A1 | M/W | CS | 0.27 MAX | 0.93 MAX | 0.048 | 0.058 | 0.10 MAX | 312 MAX | 255 MIN | 30 |

| DIN/17175/ST35.8 | A/W | CS | 0.17 MAX | 0.40 MIN | 0.040 | 0.040 | 0.35 MAX | 340-441 | 235 MIN | 25 |

| DIN/17175/ST45.8 | A/W | CS | 0.22 MAX | 0.45 MIN | 0.040 | 0.040 | 0.10-0.35 | 441-540 | 255 MIN | 21 |

| IS 3074 CDS1 | A/W | CS | 0.20 MAX | 0.30-0.60 | 0.050 | 0.050 | -- | 432 | 373 | -- |

| IS 3074 CDS2 | A/W | CS | 0.10-0.18 | 0.40-0.80 | 0.050 | 0.050 | -- | 432 | 373 | -- |

| IS 3074 CDS3 | A/W | CS | 0.10-0.18 | 0.40-0.80 | 0.050 | 0.050 | -- | 432 | 373 | -- |

| IS 3074 CDS4 | A/W | CS | 0.10-0.18 | 0.60-0.90 | 0.050 | 0.050 | -- | 569 | 461 | -- |

| IS 3074 CDS5 | A/W | CS | 0.10-0.18 | 0.60-0.90 | 0.050 | 0.050 | -- | 687 | 589 | -- |

| DIN 2391 PART1 5T-35 | -- | CS | 0.17 | >0.04 | 0.050 | 0.050 | 0.35 | 432 | - | 5% |

| DIN 2391 PART1 5T-45 | -- | CS | 0.21 | >0.04 | 0.050 | 0.050 | 0.35 | 540 | -- | 5% |

| BS 6323 PART 4 | -- | CS | 0.25 MAX | 1.25 MAX | 0.050 | 0.050 | 0.35 | 520 | 415 | 5% |

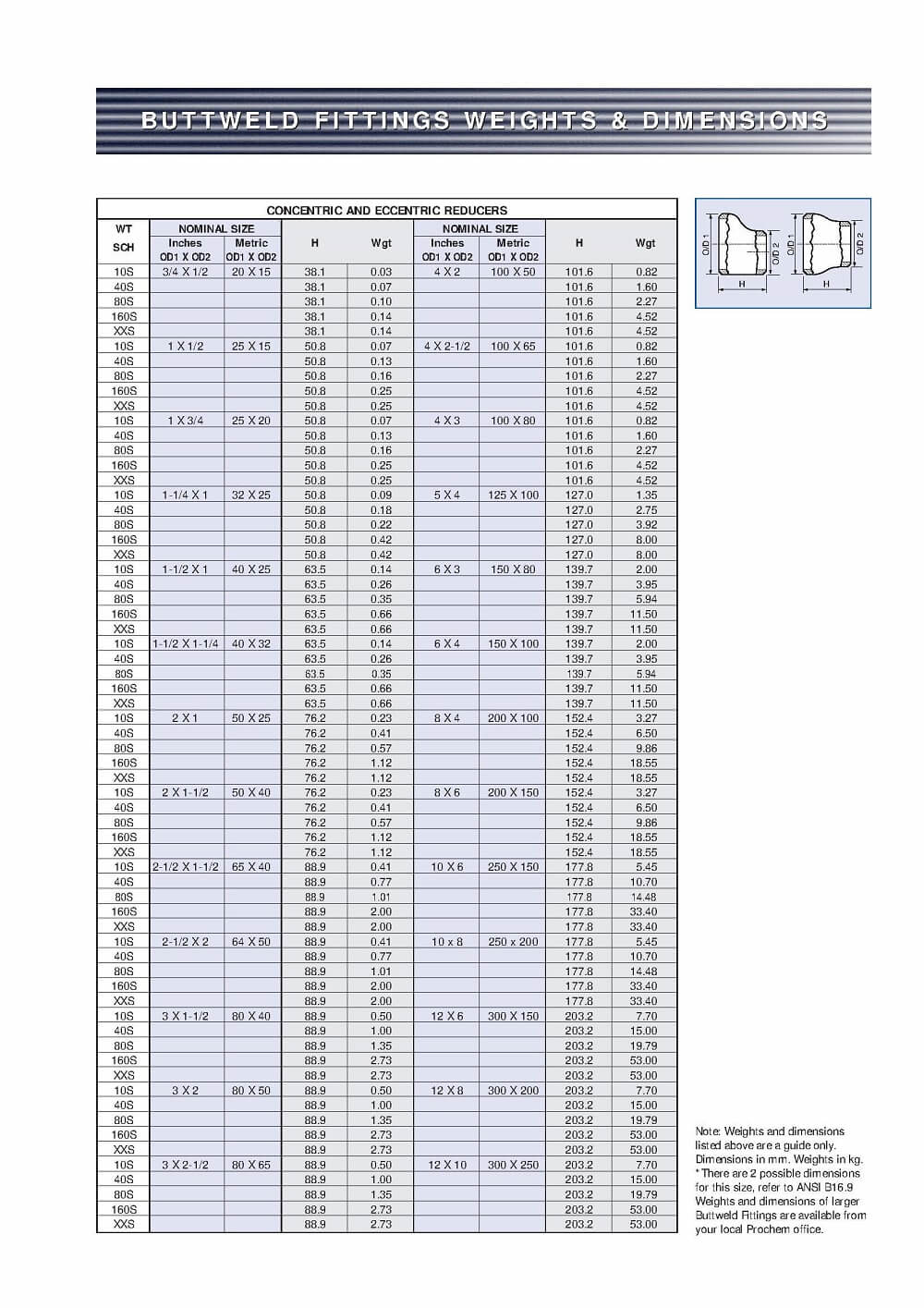

Buttweld Fittings

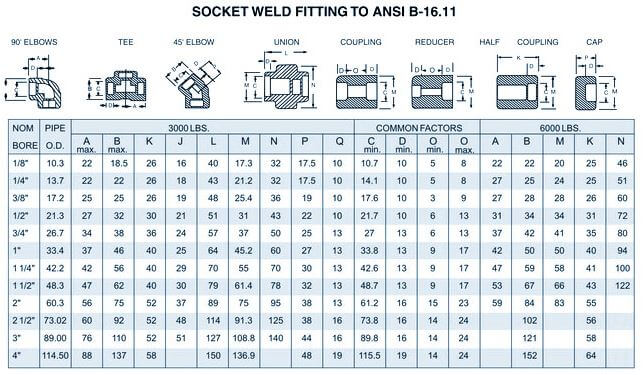

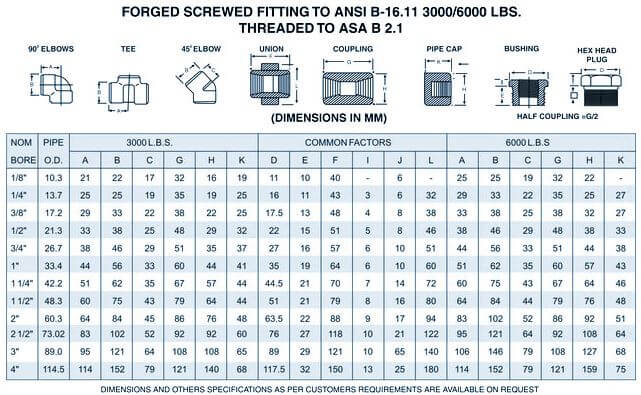

Socketweld Fittings

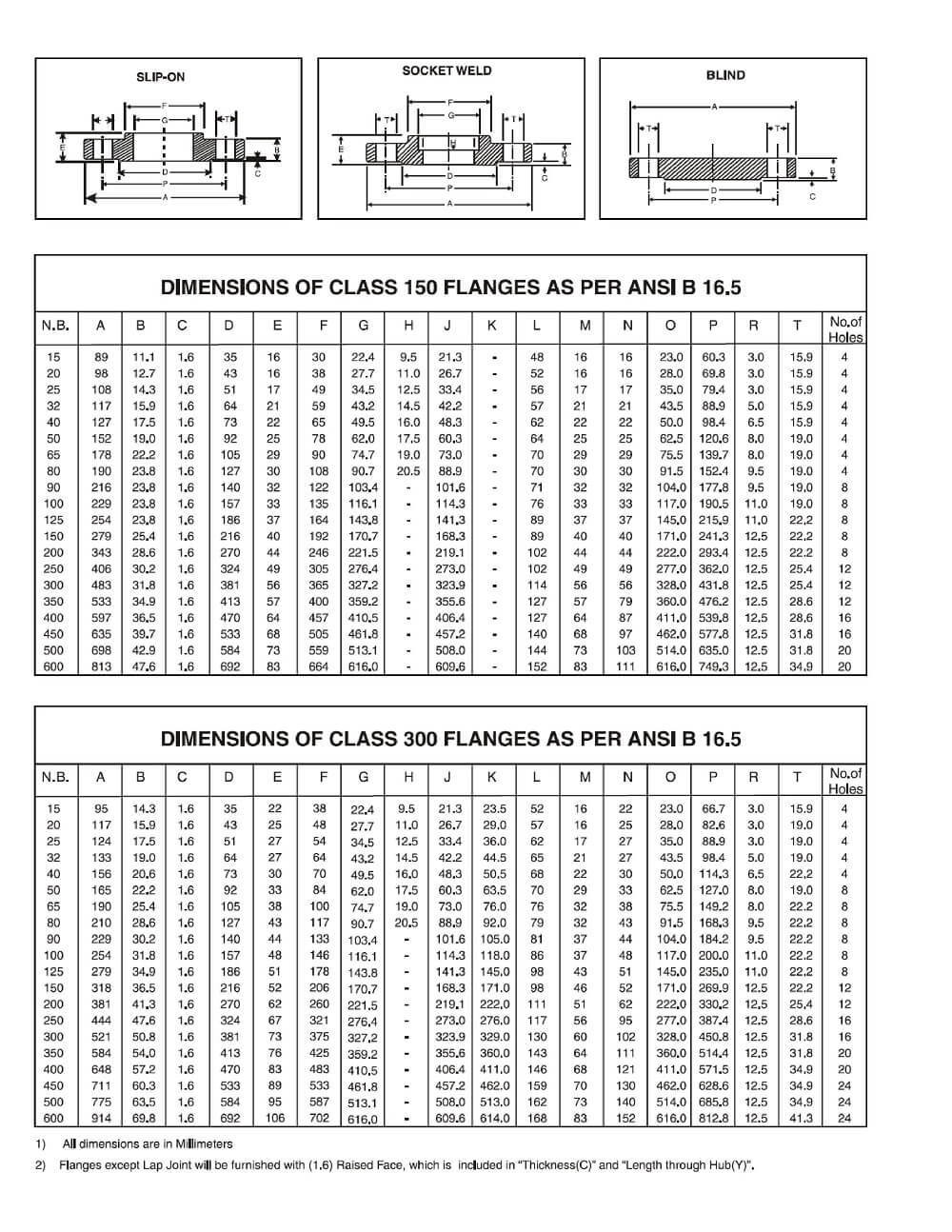

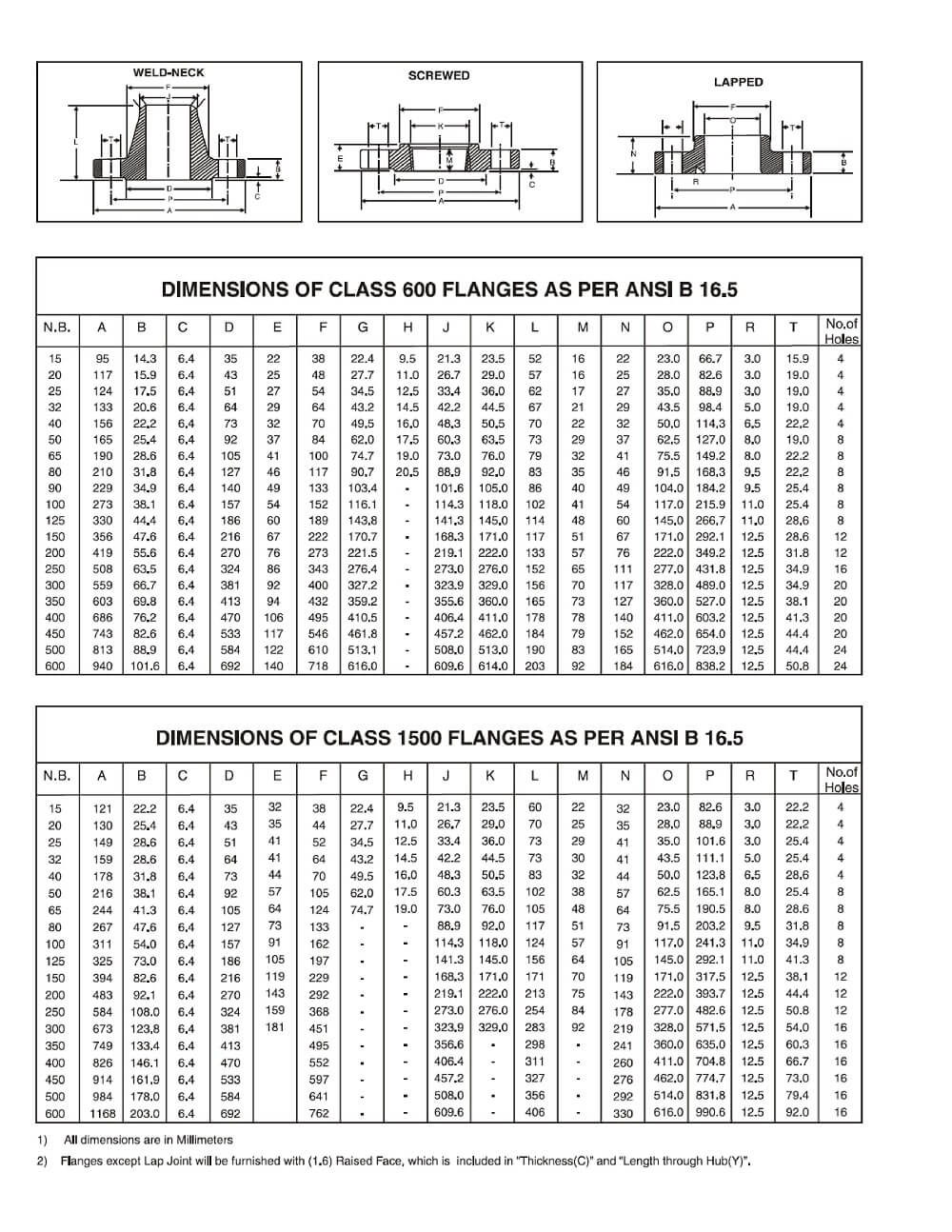

Flange Dimensions ANSI B-16.5

Flange Dimensions BS10

TABLE D - For Working Steam Pressure upto 50 lbs per sq. Inch:

| Nominal Pipe Size | O. D. of pipe | O. D. | P. C. D. | No. of bolt | Dia of bolt | Thickness |

|---|---|---|---|---|---|---|

| 1/2" | 21.3 | 95.3 | 66.7 | 4 | 12.7 | 4.8 |

| 3/4" | 26.7 | 101.6 | 73.0 | 4 | 12.7 | 4.8 |

| 1" | 33.4 | 114.3 | 82.6 | 4 | 12.7 | 4.8 |

| 1.1/4" | 42.2 | 120.7 | 87.3 | 4 | 12.7 | 6.4 |

| 1.1/2" | 48.3 | 133.4 | 98.4 | 4 | 12.7 | 6.4 |

| 2" | 60.3 | 152.4 | 114.3 | 4 | 15.9 | 7.9 |

| 2.1/2" | 73.0 | 165.1 | 127.0 | 4 | 15.9 | 7.9 |

| 3" | 88.9 | 184.2 | 146.1 | 4 | 15.9 | 9.5 |

| 3.1/2" | 101.6 | 203.2 | 165.1 | 4 | 15.9 | 9.5 |

| 4" | 114.3 | 215.9 | 177.8 | 4 | 15.9 | 9.5 |

| 5" | 141.3 | 254.0 | 209.6 | 8 | 15.9 | 12.7 |

| 6" | 168.3 | 279.4 | 228.6 | 8 | 15.9 | 12.7 |

| 7" | 190.5 | 304.8 | 260.4 | 8 | 15.9 | 12.7 |

| 8" | 219.1 | 336.6 | 292.1 | 8 | 15.9 | 12.7 |

| 9" | 244.5 | 368.3 | 323.9 | 8 | 15.9 | 15.9 |

| 10" | 273.0 | 406.4 | 355.6 | 8 | 19.1 | 15.9 |

| 12" | 323.9 | 457.2 | 406.4 | 12 | 19.1 | 15.9 |

| 14" | 355.6 | 527.1 | 469.9 | 12 | 22.2 | 19.1 |

| 16" | 406.4 | 577.9 | 520.7 | 12 | 22.2 | 19.1 |

| 18" | 457.2 | 641.4 | 584.2 | 12 | 22.2 | 22.2 |

| 20" | 508.0 | 704.9 | 641.4 | 16 | 22.5 | 25.4 |

| 24" | 609.6 | 825.5 | 755.7 | 16 | 25.4 | 28.6 |

TABLE E - For Working Steam Pressure upto 100 lbs per sq. Inch:

| Nominal Pipe Size | O. D. of pipe | O. D. | P. C. D. | No. of bolt | Dia of bolt | Thickness |

|---|---|---|---|---|---|---|

| 1/2" | 21.3 | 95.3 | 66.3 | 4 | 12.7 | 6.4 |

| 3/4" | 26.7 | 101.6 | 73.0 | 4 | 12.7 | 6.4 |

| 1" | 33.4 | 114.3 | 82.6 | 4 | 12.7 | 7.1 |

| 1.1/4" | 42.2 | 120.7 | 87.3 | 4 | 12.7 | 7.9 |

| 1.1/2" | 48.3 | 133.4 | 98.4 | 4 | 12.7 | 8.7 |

| 2" | 60.3 | 152.4 | 114.3 | 4 | 15.9 | 9.5 |

| 2.1/2" | 73.0 | 165.1 | 127.0 | 4 | 15.9 | 10.3 |

| 3" | 88.9 | 184.2 | 146.1 | 4 | 15.9 | 11.1 |

| 3.1/2" | 101.6 | 203.2 | 165.1 | 8 | 15.9 | 11.9 |

| 4" | 114.3 | 215.9 | 177.8 | 8 | 15.9 | 12.7 |

| 5" | 141.3 | 254.0 | 209.6 | 8 | 15.9 | 14.3 |

| 6" | 168.3 | 279.4 | 228.6 | 8 | 19.1 | 17.5 |

| 7" | 190.5 | 304.8 | 260.4 | 8 | 19.1 | 19.1 |

| 8" | 219.1 | 336.6 | 292.1 | 8 | 19.1 | 19.1 |

| 9" | 244.5 | 368.3 | 323.9 | 12 | 19.1 | 20.6 |

| 10" | 273.0 | 406.4 | 355.6 | 12 | 19.1 | 22.2 |

| 12" | 323.9 | 257.2 | 406.4 | 12 | 22.2 | 25.4 |

| 14" | 355.6 | 527.2 | 469.9 | 12 | 22.2 | 25.4 |

| 16" | 406.4 | 577.9 | 520.7 | 12 | 22.2 | 25.4 |

| 18" | 457.2 | 641.4 | 584.2 | 16 | 22.2 | 28.6 |

| 20" | 508.0 | 704.9 | 647.4 | 16 | 22.2 | 31.8 |

| 24" | 609.6 | 825.5 | 755.7 | 16 | 25.4 | 38.1 |

TABLE F - For Working Steam Pressure above 100 lbs and upto 150 lbs per sq. Inch:

| Nominal Pipe Size | O. D. of pipe | O. D. | P. C. D. | No. of bolt | Dia of bolt | Thickness |

|---|---|---|---|---|---|---|

| 1/2" | 21.3 | 95.3 | 66.7 | 4 | 12.7 | 9.5 |

| 3/4" | 26.7 | 101.6 | 73.0 | 4 | 12.7 | 9.5 |

| 1" | 33.4 | 120.7 | 87.3 | 4 | 15.9 | 9.5 |

| 1.1/4" | 42.2 | 133.4 | 98.4 | 4 | 15.9 | 12.7 |

| 1.1/2" | 48.3 | 139.7 | 104.8 | 4 | 15.9 | 12.7 |

| 2" | 60.3 | 165.1 | 127.0 | 4 | 15.9 | 15.9 |

| 2.1/2" | 73.0 | 184.2 | 146.1 | 8 | 15.9 | 15.9 |

| 3" | 88.9 | 203.2 | 165.1 | 8 | 15.9 | 15.9 |

| 3.1/2" | 101.6 | 215.9 | 177.8 | 8 | 15.9 | 19.1 |

| 4" | 114.3 | 228.6 | 190.5 | 8 | 15.9 | 19.1 |

| 5" | 141.3 | 279.4 | 235.0 | 8 | 19.1 | 22.2 |

| 6" | 168.3 | 304.8 | 260.4 | 12 | 19.1 | 22.2 |

| 7" | 190.5 | 336.6 | 292.1 | 12 | 19.1 | 22.2 |

| 8" | 219.1 | 368.3 | 323.9 | 12 | 19.1 | 25.4 |

| 9" | 244.5 | 406.4 | 355.6 | 12 | 22.2 | 25.4 |

| 10" | 273.0 | 431.8 | 381.0 | 12 | 22.2 | 25.4 |

| 12" | 323.9 | 489.0 | 438.2 | 16 | 22.2 | 28.6 |

| 14" | 355.6 | 552.5 | 495.3 | 16 | 25.4 | 31.8 |

| 16" | 406.4 | 609.6 | 552.5 | 20 | 25.4 | 31.8 |

| 18" | 457.2 | 673.1 | 609.6 | 20 | 28.6 | 34.9 |

| 20" | 508.0 | 736.6 | 673.1 | 24 | 28.6 | 38.1 |

| 24" | 609.6 | 850.9 | 781.1 | 24 | 318 | 41.3 |

TABLE H - For Working Steam Pressure above 150 lbs and upto 250 lbs per sq. Inch:

| Nominal Pipe Size | O. D. of pipe | O. D. | P. C. D. | No. of bolt | Dia of bolt | Thickness |

|---|---|---|---|---|---|---|

| 1/2" | 21.3 | 114.3 | 82.6 | 4 | 15.9 | 12.7 |

| 3/4" | 26.7 | 114.3 | 82.6 | 4 | 15.9 | 12.7 |

| 1" | 33.4 | 120.7 | 87.3 | 4 | 15.9 | 14.3 |

| 1.1/4" | 42.2 | 133.4 | 98.4 | 4 | 15.9 | 17.5 |

| 1.1/2" | 48.3 | 139.7 | 104.8 | 4 | 15.9 | 17.5 |

| 2" | 60.3 | 165.1 | 127.0 | 4 | 15.9 | 19.1 |

| 2.1/2" | 73.0 | 184.2 | 146.1 | 8 | 15.9 | 19.1 |

| 3" | 88.9 | 203.2 | 165.1 | 8 | 15.9 | 22.2 |

| 3.1/2" | 101.6 | 215.9 | 177.8 | 8 | 15.9 | 22.2 |

| 4" | 114.3 | 228.6 | 190.5 | 8 | 15.9 | 25.4 |

| 5" | 141.3 | 279.4 | 235.0 | 8 | 19.1 | 28.6 |

| 6" | 168.3 | 304.8 | 260.4 | 12 | 19.1 | 28.6 |

| 7" | 190.5 | 336.6 | 292.1 | 12 | 19.1 | 31.8 |

| 8" | 219.1 | 368.3 | 323.9 | 12 | 19.1 | 31.8 |

| 9" | 244.5 | 406.4 | 355.6 | 12 | 22.2 | 34.9 |

| 10" | 273.0 | 431.8 | 381.0 | 12 | 22.2 | 34.9 |

| 12" | 323.9 | 489.0 | 438.2 | 16 | 22.2 | 38.1 |

| 14" | 355.6 | 552.5 | 495.3 | 16 | 25.4 | 41.3 |

| 16" | 406.4 | 609.6 | 552.5 | 20 | 25.4 | 44.5 |

| 18" | 457.2 | 673.1 | 609.6 | 20 | 28.6 | 47.6 |

| 20" | 508.0 | 736.6 | 673.1 | 24 | 28.6 | 50.8 |

| 24" | 609.6 | 850.9 | 781.1 | 24 | 31.8 | 57.2 |

Flange Dimensions BS4504 PN 16

DN = Nominal size, D = Outside Diameter, A = Outside Dia of Neck , B1 = Bore of Type 101 & 112 Flange, C1 = Thickness of Plate Flange,

C2 = Thickness of Weld_Neck and Boss Flange , N1 = Dia of Weld Neck , N2 = Dia of Boss ,R = corner Radius, H1 = Length of Boss Flange,

H2 = Length of Weld Neck Flange, H3 = Length of Neck :

Note: The flanges shown are only a small part of the range covered in BS 4504.

The Facings shown are type B (Raised Face). Other Facings include:

Type A..Flat: Type C..Tongue: Type D..Groove Type E..Spigot: :Type F..Recess: Type G..O-ring Recess: Type H.,0-ring Groove:

| DN | D | C1 | C2 | H1 | H2 | H3 | R | A | N1 | N2 | B1 | d1 | f1 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 90 | 14 | 14 | 20 | 35 | 6 | 3 | 17,2 | 28 | 30 | 18 | 40 | 2 |

| 15 | 95 | 14 | 14 | 20 | 35 | 6 | 3 | 21,3 | 32 | 35 | 22 | 45 | 2 |

| 20 | 105 | 14 | 14 | 24 | 38 | 6 | 4 | 26,9 | 39 | 45 | 27,5 | 58 | 2 |

| 25 | 115 | 16 | 16 | 24 | 38 | 6 | 4 | 33,7 | 46 | 52 | 34,5 | 68 | 2 |

| 32 | 140 | 18 | 16 | 26 | 40 | 6 | 5 | 42,4 | 56 | 60 | 43,5 | 78 | 2 |

| 40 | 150 | 18 | 16 | 26 | 42 | 7 | 5 | 48,3 | 64 | 70 | 49,5 | 88 | 3 |

| 50 | 165 | 20 | 18 | 28 | 45 | 8 | 5 | 60,3 | 74 | 84 | 61,5 | 102 | 3 |

| 65 | 185 | 20 | 18 | 32 | 45 | 10 | 6 | 76,1 | 92 | 104 | 77,5 | 122 | 3 |

| 80 | 200 | 20 | 20 | 34 | 50 | 10 | 6 | 88,9 | 110 | 118 | 90,5 | 138 | 3 |

| 100 | 220 | 22 | 20 | 40 | 52 | 12 | 6 | 114,3 | 130 | 140 | 116 | 162 | 3 |

| 125 | 250 | 22 | 22 | 44 | 55 | 12 | 6 | 139,7 | 158 | 168 | 141,5 | 188 | 3 |

| 150 | 285 | 24 | 22 | 44 | 55 | 12 | 8 | 168,3 | 184 | 195 | 170,5 | 212 | 3 |

| 200 | 340 | 26 | 24 | 44 | 62 | 16 | 8 | 219,1 | 234 | 246 | 221,5 | 268 | 3 |

| 250 | 405 | 29 | 26 | 46 | 70 | 16 | 10 | 273 | 288 | 298 | 276,5 | 320 | 3 |

| 300 | 460 | 32 | 28 | 46 | 78 | 16 | 10 | 323,9 | 342 | 350 | 327,5 | 378 | 4 |

| 350 | 520 | 35 | 30 | 57 | 82 | 16 | 10 | 355,6 | 390 | 400 | 359 | 438 | 4 |

| 400 | 580 | 38 | 32 | 63 | 85 | 16 | 10 | 406,4 | 444 | 456 | 411,0 | 490 | 4 |

| 450 | 640 | 42 | 34 | 68 | 87 | 16 | 12 | 457,0 | 490 | 502 | 462,0 | 550 | 4 |

| 500 | 715 | 46 | 34 | 73 | 90 | 16 | 12 | 508,0 | 546 | 559 | 513,5 | 610 | 4 |

| 600 | 840 | 52 | 36 | 83 | 95 | 18 | 12 | 610,0 | 650 | 658 | 616,5 | 725 | 5 |

| 700 | 910 | 60 | 36 | 83 | 100 | 18 | 12 | 711,0 | 750 | 760 | - | 795 | 5 |

| 800 | 1025 | 68 | 38 | 90 | 105 | 20 | 12 | 813,0 | 848 | 864 | - | 900 | 5 |

| 900 | 1125 | 76 | 40 | 94 | 110 | 20 | 12 | 914,0 | 948 | 968 | - | 1000 | 5 |

| 1000 | 1255 | 84 | 42 | 100 | 120 | 22 | 12 | 1016,0 | 1056 | 1072 | - | 1115 | 5 |

| 1200 | 1485 | 98 | 48 | - | 130 | 30 | 12 | 1220,0 | 1260 | - | - | 1330 | 5 |

| 1400 | 1685 | - | 52 | - | 145 | 30 | 12 | 1420,0 | 1465 | - | - | 1530 | 5 |

| 1600 | 1930 | - | 58 | - | 160 | 35 | 12 | 1620,0 | 1668 | - | - | 1750 | 5 |

FLANGE BOLTING:

K = Bolt Circle Diameter, L = Dia Of Bolt Hole,

No = Number of Holes , Size = Size of Bolts

| DN | K | L | No | Size |

|---|---|---|---|---|

| mm | mm | mm | - | mm |

| 10 | 60 | 14 | 4 | M12 |

| 15 | 65 | 14 | 4 | M12 |

| 20 | 75 | 14 | 4 | M12 |

| 25 | 85 | 14 | 4 | M12 |

| 32 | 100 | 18 | 4 | M16 |

| 40 | 110 | 18 | 4 | M16 |

| 50 | 125 | 18 | 4 | M16 |

| 65 | 145 | 18 | 8 | M16 |

| 80 | 160 | 18 | 8 | M16 |

| 100 | 180 | 18 | 8 | M16 |

| 125 | 210 | 18 | 8 | M16 |

| 150 | 240 | 22 | 8 | M20 |

| 200 | 295 | 22 | 12 | M20 |

| 250 | 355 | 26 | 12 | M24 |

| 300 | 410 | 26 | 12 | M24 |

| 350 | 470 | 26 | 16 | M24 |

| 400 | 525 | 30 | 16 | M27 |

| 450 | 585 | 30 | 20 | M27 |

| 500 | 650 | 33 | 20 | M30 |

| 600 | 770 | 36 | 20 | M33 |

| 700 | 840 | 36 | 24 | M33 |

| 800 | 950 | 39 | 24 | M36 |

| 900 | 1050 | 39 | 28 | M36 |

| 1000 | 1170 | 42 | 28 | M39 |

| 1200 | 1390 | 48 | 32 | M45 |

| 1400 | 1590 | 48 | 36 | M45 |

| 1600 | 1820 | 56 | 40 | M52 |

BS EN 1092-1 PN 25 Dimensions:

DN = Nominal size, D = Outside Diameter, A = Outside Dia of Neck , B1 = Bore of Type 01 & 12 Flange, C1 = Thickness of Plate Flange,

C2 = Thickness of Weld_Neck and Boss Flange , N1 = Dia of Weld Neck , N2 = Dia of Boss ,R = corner Radius, H1 = Length of Boss Flange,

H2 = Length of Weld Neck Flange, H3 = Length of Neck : S = neck thickness:

Note: The flange types shown are only a small part of the range covered in BS EN 1092-1.

- type 05 is a blank flange

- type13 is a screwed boss flange

- type 02 is a loose plate flange used with either a type 32 weld on plate collar or a type 33 lapped pipe end

- a type 04 flange is a loose flange for use with a type 34 a weld-neck collar

- type 21 is an integral flange

The Facings shown are type B (Raised Face). Other Facings include:

Type A..Flat: Type C..Tongue: Type D..Groove Type E..Spigot: :Type F..Recess: Type G..O-ring Spigot: Type H.,0-ring Groove:

A typical designation for a flange would be BS EN 1092-1/01B/DN150/PN25/ */S235JR

Key: = Standard No/Flange Type & Face Type / Nominal Size/ Pressure Rating/*/ Material Designation.

* Normally not used. For 01 type flanges above 600 mm the bore B1 would be specified here . * for type 11 and 31 the neck thickness (S) is specified here.

An example designation for an flange for an 800mm pipe ... BS EN 1092-1/01B/DN800/PN25/818/S235JR

This is an extremely simplified note. To obtain a comprehensive description with the various variations the standards must be used.Note : All Dimensions in mm

| DN | D | C1 | C2 | H1 | H2 | H3 | R | A | N1 | N2 | B1 | d1 | f1 | S |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 90 | 14 | 14 | 20 | 35 | 6 | 4 | 17,2 | 28 | 30 | 18 | 40 | 2 | 1,8 |

| 15 | 95 | 14 | 14 | 20 | 35 | 6 | 4 | 21,3 | 32 | 35 | 22 | 45 | 2 | 2,0 |

| 20 | 105 | 14 | 14 | 24 | 38 | 6 | 4 | 26,9 | 39 | 45 | 27,5 | 58 | 2 | 2,3 |

| 25 | 115 | 16 | 16 | 24 | 38 | 6 | 4 | 33,7 | 46 | 52 | 34,5 | 68 | 2 | 2,6 |

| 32 | 140 | 18 | 16 | 26 | 40 | 6 | 6 | 42,4 | 56 | 60 | 43,5 | 78 | 2 | 2,6 |

| 40 | 150 | 18 | 16 | 26 | 42 | 7 | 6 | 48,3 | 64 | 70 | 49,5 | 88 | 2 | 2,6 |

| 50 | 165 | 20 | 20 | 34 | 48 | 8 | 6 | 60,3 | 75 | 84 | 61,5 | 102 | 2 | 2,9 |

| 65 | 185 | 22 | 22 | 38 | 52 | 10 | 6 | 76,1 | 90 | 104 | 77,5 | 122 | 2 | 2,9 |

| 80 | 200 | 24 | 24 | 40 | 58 | 12 | 8 | 88,9 | 105 | 118 | 90,5 | 138 | 2 | 3,2 |

| 100 | 235 | 26 | 24 | 44 | 65 | 12 | 8 | 114,3 | 134 | 145 | 116 | 162 | 2 | 3,6 |

| 125 | 270 | 28 | 26 | 48 | 68 | 12 | 10 | 139,7 | 162 | 170 | 141,5 | 188 | 2 | 4,2 |

| 150 | 300 | 30 | 28 | 52 | 75 | 12 | 10 | 168,3 | 192 | 200 | 170,5 | 218 | 2 | 4,5 |

| 200 | 360 | 32 | 30 | 52 | 80 | 16 | 10 | 219,1 | 244 | 256 | 221,5 | 278 | 2 | 6,3 |

| 250 | 425 | 35 | 32 | 60 | 88 | 18 | 12 | 273,0 | 298 | 310 | 276,5 | 335 | 2 | 7,1 |

| 300 | 485 | 38 | 34 | 67 | 92 | 18 | 12 | 323,9 | 352 | 364 | 327,5 | 395 | 2 | 8,0 |

| 350 | 555 | 42 | 38 | 72 | 100 | 20 | 12 | 355,6 | 398 | 418 | 359,5 | 450 | 2 | 8,0 |

| 400 | 620 | 46 | 40 | 78 | 110 | 20 | 12 | 406,4 | 452 | 472 | 411,0 | 505 | 2 | 8,8 |

| 450 | 670 | 50 | 46 | 84 | 110 | 20 | 12 | 457,0 | 500 | 520 | 462,0 | 555 | 2 | 8,8 |

| 500 | 730 | 56 | 48 | 90 | 125 | 20 | 12 | 508,0 | 558 | 580 | 513,5 | 615 | 2 | 10,0 |

| 600 | 845 | 68 | 58 | 100 | 125 | 20 | 12 | 610,0 | 660 | 684 | 616,5 | 720 | 2 | 11,0 |

| 700 | 960 | - | 46 | - | 125 | 20 | 12 | 711,0 | 760 | - | - | 820 | 2 | 12,5 |

| 800 | 1085 | - | 50 | - | 135 | 22 | 12 | 813,0 | 864 | - | - | 930 | 2 | 14,2 |

| 900 | 1185 | - | 54 | - | 145 | 24 | 12 | 914,0 | 968 | - | - | 1030 | 2 | 16,0 |

| 1000 | 1320 | - | 58 | - | 155 | 24 | 16 | 1016,0 | 1070 | - | - | 1140 | 2 | 17,5 |

| 1200 | 1530 | - | - | - | - | - | 18 | 1219,0 | - | - | - | 1350 | 2 | - |

| 1400 | 1755 | - | - | - | - | - | 18 | 1422,0 | - | - | - | 1560 | 2 | - |

| 1600 | 1975 | - | - | - | - | - | 20 | 1626,0 | - | - | - | 1780 | 2 | - |

| DN | D | C1 | C2 | H1 | H2 | H3 | R | A | N1 | N2 | B1 | d1 | f1 | S |

Note: in BS EN 1092-1:2002 f1= 2 for all sizes.

In the latest versions of the relevant DIN standard. f1 varies as follow

(DN =< 32 f1 = 1-2, DN 32->250(inc) f1= 1-3, DN 250->500(inc) f1= 1-4, Dn >500 f1= 1-5 )..

Flange Bolting:

K = Bolt Circle Diameter, L = Dia Of Bolt Hole,

No = Number of Holes , Size = Size of Bolts

| DN | K | L | No | Size |

|---|---|---|---|---|

| mm | mm | mm | - | mm |

| 10 | 60 | 14 | 4 | M12 |

| 15 | 65 | 14 | 4 | M12 |

| 20 | 75 | 14 | 4 | M12 |

| 25 | 85 | 14 | 4 | M12 |

| 32 | 100 | 18 | 4 | M16 |

| 40 | 110 | 18 | 4 | M16 |

| 50 | 125 | 18 | 4 | M16 |

| 65 | 145 | 18 | 8 | M16 |

| 80 | 160 | 18 | 8 | M16 |

| 100 | 190 | 22 | 8 | M20 |

| 125 | 220 | 26 | 8 | M24 |

| 150 | 250 | 26 | 8 | M24 |

| 200 | 310 | 26 | 12 | M24 |

| 250 | 370 | 30 | 12 | M27 |

| 300 | 430 | 30 | 16 | M27 |

| 350 | 490 | 33 | 16 | M30 |

| 400 | 550 | 36 | 16 | M33 |

| 450 | 600 | 36 | 20 | M33 |

| 500 | 660 | 36 | 20 | M33 |

| 600 | 770 | 39 | 20 | M36 |

| 700 | 875 | 42 | 24 | M39 |

| 800 | 990 | 48 | 24 | M45 |